Steel shapes the world around us. It helps us materialize structures of such magnitude that they defy our imagination.

Soaring skyscrapers, gigantic stadiums, otherwordly musems—such feats of engineering are made possible with steel.

The process of using structural and cold formed steel to frame, or form the skeleton of a building, has been at the backbone of the construction industry for centuries.

What’s the difference between the two? Let’s find out.

Why Do We Build With Steel?

Steel is one the most cost effective and durable building materials.

Out of all construction materials, steel boasts the highest strength-to-weight-ratio.

The amount of weight that a steel beam or column can support, generally surpasses that of concrete or wood at the same mass.

A cold formed steel stud can span relatively greater distances, without needing additional thicker or heavier components—resulting in light yet strong structures.

As a result, steel framed structures are efficient, allowing builders to minimize materials used without compromising on functionality.

At the same time, steel is renowned for its high tensile strength, allowing it to flex under loads that would cause other materials to crack or break.

This allows steel framed buildings to reliably withstand dynamic forces such as seismic activity or high winds.

Furthermore, steel framing is considered an environmentally friendly material due to recyclability of steel.

Learn more about benefits of building with light gauge steel:

Structural Steel Framing

Structural steel has many uses, but the most common are large projects such as ships and skyscraper buildings. It is extremely durable and trusted as a primary steel framing system for tall buildings.

As opposed to light gauge steel, structural steel is used to frame large scale structures such as high-rise buildings and bridges, industrial facilities.

Here are a few examples of structures that would require structural steel framing:

● Stadiums

● Skyscrapers

● Aircraft hangars

● Hospitals

● Wind Turbines

● Suspension bridges

● Oil platforms

Structural steel is produced through methods such as blast furnace and electric arc furnace. These are also primary steel-making methods.

Both of these methods utilize immense heat to purify iron into steel.

The resultant steel is rolled or molded into shapes used for construction purposes – I shaped beams, L shaped sections and so on.

These sections are generally heavier and larger than cold formed metal sections. A 2 storey residential building is better suited to using cold formed steel components. Likewise, a high-rise structure which is subject to much greater and varied loads, would require stronger structural steel components.

The benefits of structural steel are mostly synonymous with cold formed steel.

However structural steel is heavier, and therefore costlier to transport, and requires cranes to build with.

One more reason why structural steel is used for relatively larger structures, and not small to mid-rise structures which cold formed steel is adequate for.

Cold Formed Steel Framing

Cold formed steel framing is perfect for small to mid-scale projects that are up to 4 to 6 storeys. These include but are not limited to:

- Modular homes

- Hospital rooms

- Malls and retail stores

- Schools

Cold formed steel is created by rolling thin strips of steel at room temperature – as opposed to the molten hot temperatures required to produce structural steel.

Metal studs are the elementary components of any cold formed steel structure. Before being brought to the job-site, they are rolled into various shapes depending on how they will be used.

These studs are also known as C studs, Z studs, U tracks.

Once their desired shape is achieved, the studs are sprayed with a protective coating. This coating can be aluminum, zinc, or sometimes a mixture of the two.

Another common substitute for cold formed steel framing is wood, especially for residential construction in North America.

Countries such as Sweden, Japan and even Canada (in the province of Vancouver) however use wood products for public infrastructure.

Granted, the wood used for these structures (cross laminated timber) is equivalent to structural steel instead of cold formed steel.

And with the right harvesting practices, wood can be used sustainable and is arguably more environmentally friendly compared to cold formed steel.

However steel offers various benefits that are unique to this material, and they are not all to do with its structural durability.

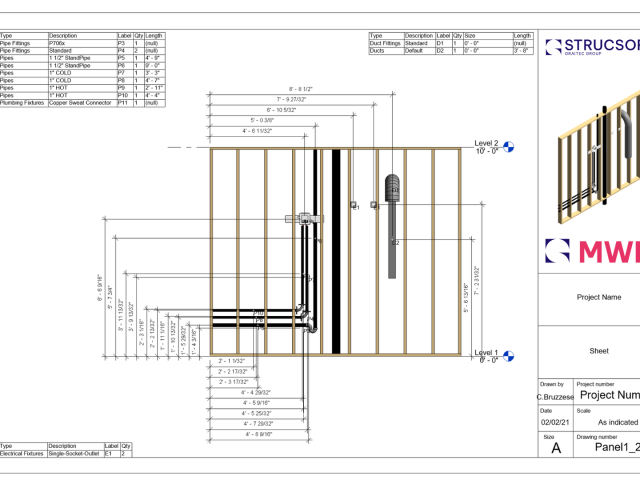

Steel has a uniform shape that allows a level of design flexibility. Steel sections can be designed in a CAD platform, and sent off to a CNC machine to create repeatable and reliable designs.

This can be used to produce a large number of structures in a relatively shorter amount of time. It also means steel has a wider use case.

Explore the differences between cold formed steel and wood framing

Your next project made easier

Steel can help make your blueprints materialize into the buildings that you envisioned. It’s durable, long-lasting, cost-effective, and good for the environment.

It’s a great option if you’re building your next home, or even if you’re building the next iconic skyscraper.

Begin your free MWF Pro Metal or MWF Advanced Metal trial and start your next building project today.

For more information on our products or design services, visit strucsoftsolutions.com, email us at info@strucsoftsolutions.com or call us at 514-538-6862.

Get started with your free trial now

Automate design and fabrication with the industry's most comprehensive Revit® framing software.