Have you ever wondered what’s special about framing with light gauge steel, compared to other materials? Light gauge steel is both highly durable and lightweight, making it ideal for framing applications, especially when paired with steel framing software. Learn more about the advantages of using this material for your next project and why it’s the preferred choice of builders in the industry.

It significantly reduces transportation costs and simplifies the construction process as it is easy to work with. Additionally, it is pound-for-pound one of the toughest materials available, providing excellent structural integrity and durability.

By using light steel for framing your construction projects, commercial or residential, you can save valuable time and money without compromising on quality or performance—especially if you build using offsite construction methods.

Whether you’re an engineer, architect, or general contractor, it’s important to know about light gauge steel framing. This blog serves as a primer covering the essentials you need to know about LGS, or light gauge steel.

Heavy vs Light Gauge Steel Framing

Light gauge steel framing is a popular option in both residential and commercial construction due to its reliability and innovative design.

This material poses several advantages over traditional wood framing, including increased strength and durability, resistance to rot and pests, and improved fire resistance to name a few.

Light gauge steel is created through a process known as cold forming. This involves passing thin sheets of steel through rollers and presses while at room temperature, to create various shapes such as C, Z, or S-shaped sections. This method produces a final output that is highly precise and consistent in shape and design.

In contrast, heavy or structural steel is hot-rolled. In this method of steel manufacturing, the steel is heated to about 400-800 celsius and then passed through roll formers to shape them in their desired form.

This temperature range enables the steel to be shaped and formed more easily during the hot-rolling process. Structural steel components are typically thicker and heavier than light gauge steel components.

Depending on the project needs, medium-size construction can benefit from either structural steel or light gauge.

What Is Light Gauge Steel Framing?

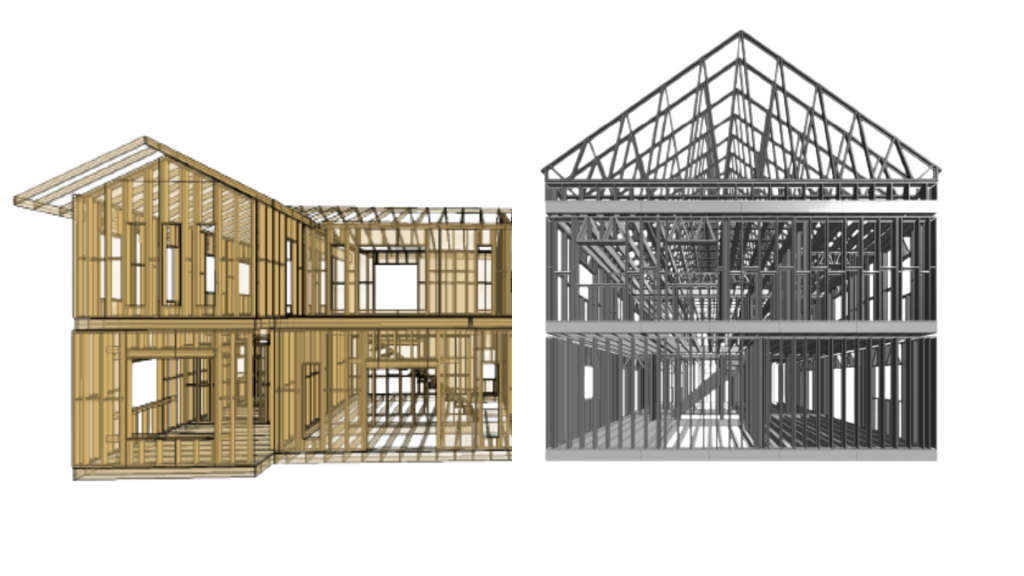

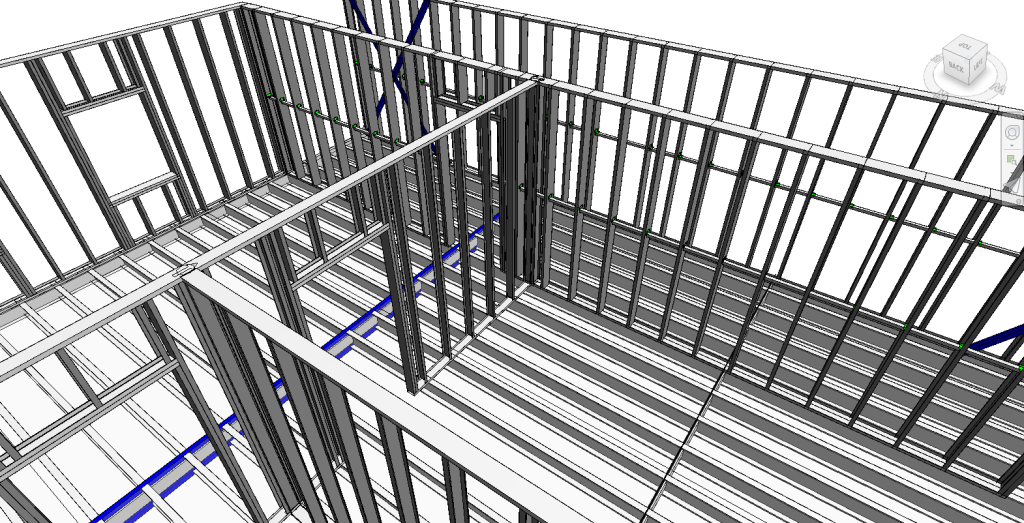

Light gauge steel framing is a construction method that cold formed steel sections to create a structural framework for buildings, which at its simplest is an assembly of columns and beams.

Cold formed steel sections include steel studs, tracks and joists that are assembled together to form the load bearing skeletal structure. However It can also be used to create interior partitions and non-load bearing walls, or curtain walls.

LGS framing is commonly used for commercial and multifamily residential buildings, and it is seeing a rise in single family residential applications as well.

To prevent fire damage, steel is coated with zinc or a combination of zinc and aluminum, also referred to as “galvanized” steel. This protective coating safeguards the steel from corrosion. The thickness of the coating depends on the intended environment of use. For instance, steel pieces intended for humid settings require a thicker coating, while those in drier regions can have a thinner coating.

Versatility of Light Gauge Steel

One of the advantages of light gauge steel framing is its precision and ease of construction. The steel components can be manufactured in a factory setting at precise specifications, ensuring consistency and accuracy during the final assembly process.

Light gauge steel framing allows for a wide range of architectural designs and layouts. It can easily be customized to fit various building configurations during the design phase. The material’s natural strength allows architects and engineers to create complex and innovative structures, including curved walls, volumetric modular pods and more.

As earlier mentioned for non-structural framing. Examples include external cladding and interior partitions. In fact, the original use for this type of construction was for interior office partitions.

Now that you know more about steel framing, let’s compare it to wood framing.

Light Gauge Steel vs Wood Framing

- Strength and Durability: Cold formed steel is stronger and more durable than wood.

- Fire Resistance: Cold formed steel is non-combustible and offers superior fire resistance.

- Consistency and Precision: Cold formed steel components are manufactured to precise specifications, ensuring consistency and accuracy.

- Design Flexibility: Cold formed steel allows for versatile architectural designs and flexible building configurations.

- Cost-Effectiveness: Cold formed steel can provide long-term cost savings due to its durability and reduced maintenance requirements.

- Sustainability: Cold formed steel is made from recycled materials and is recyclable at the end of its life cycle.

- Reduced Construction Time: Cold formed steel components are pre-engineered, leading to faster on-site assembly and shorter construction schedules.

- Dimensional Stability: Cold formed steel maintains its shape and dimensional stability, minimizing issues with warping or shrinking.

- Code Compliance: Cold formed steel construction meets or exceeds building code requirements for structural performance and safety.

Light gauge steel structures are fireproof, making them suitable for a wide range of building types. To enhance fire resistance, steel is coated with fire-rated sheeting. Additionally, since steel doesn’t decompose, rot, or warp, it makes steel an excellent alternative to wood in areas prone to termite attacks.

Note: Any light framed structure will more easily allow sound to pass through compared to solid masonry. Also, If light gauge steel isn’t properly and adequately coated with fire-rated drywall or sheeting, it will easily succumb to fire damage.

How are Light Gauge Steel Components Manufactured?

Light gauge steel or cold formed steel components are created by passing thin sheets of steel through machines known as roll formers, or simply rollers. These machines are capable of rolling the steel into the manufacturer’s desired shapes, the common ones being a “C” or “U” shape for metal studs. There are several companies in the industry that produce roll forming machines, including Howick, Knudson, Scottsdale, to name a few.

However as you may have guessed, there’s a lot that goes on before, during and after the sheets are passed through a roll former. Our clients US Frame Factory provide a detailed, down-to-the-ground look at how a metal fabricator selects the right thickness for the steel sheets, how they set up and program the roll former, and then load it onto the trucks to get to the job site. Check out the article Metal Stud Manufacturing: Light-gauge steel roll-forming

What is Revit Framing Software?

Autodesk Revit helps you make 3D models during pre-construction. Each component of your building will be identified by its function and this gives users more creative and executive control over construction documentation.

Some people might incorrectly see Revit as AutoCAD’s rival. AutoCAD is a computer-aided drafting tool with 2D and 3D drawing capabilities. However, Revit has more to offer and has already replaced AutoCAD.

StrucSoft Solutions offers professional-grade Revit framing software. You can model, coordinate, engineer, and manufacture LGS framing with MWF Pro Metal. With StrucSoft, you can take advantage of training, BIM services, custom programming, and much more.

StrucSoft’s light gauge steel Revit’s allow you to create complex steel structures with the support of a great team available anytime for advice, tips, and answers to any questions you may have. This light gauge steel framing software produces precise manufacturing data and has built-in intelligence capabilities.

Streamline the Job With Light Gauge Steel

Your budget, productivity, and workload will become more efficient by choosing light gauge steel framing. Help streamline your project. And remember, “light” steel doesn’t mean “weak” steel.

Termites, fire, and rot are no match for this type of framing, while wood is a magnet for them. Forget using heavy machines and cranes – always needed with structural steel – when you can do it all by hand (and a few tools) for small to medium projects!

If you are interested in finding out what StrucSoft can do for you, start your free trial.

For more information on our products or design services,

visit strucsoftsolutions.com/products or email us at info@strucsoftsolutions.com.

Try MWF Revit® Framing Software

Automate design and fabrication with the industry's most comprehensive Revit® framing software.

StrucSoft Solutions | Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.