MWF client’s Construction Services Group (or CSG) located in Baton Rouge, Louisiana produces custom light gauge steel framing components for many styles of building ranging from single or multifamily units, restaurants, and retail facilities.

Whether the demand is for a full steel framing solution, structural walls, or partition walls, CSG will design light gauge steel studs to fit your exact project needs – cutting each element using a Howick roll former to the specific measurements provided by construction documentation. They also have a hot rolled steel division to supplement the light gauge steel frames and to further their services to clients.

Process:

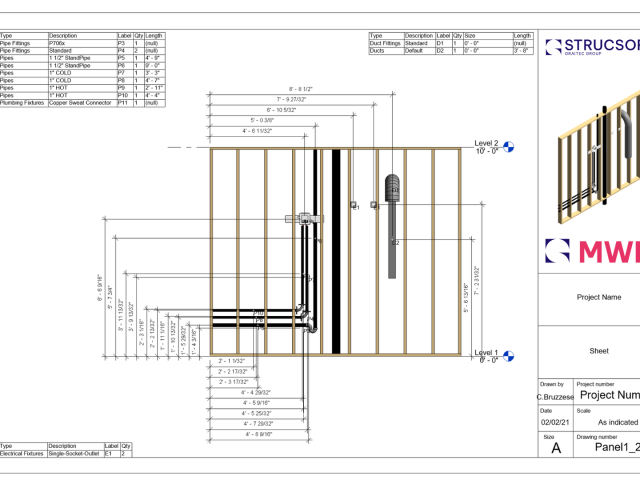

With the ability to produce framing elements in a range of gauges and customized lengths, using MWF Advanced Metal, CSG is able to export wall, floor, ceiling and truss information directly into a format readable by a Howick CNC machine.

Richard Tilley, Director of Development at CSG explains: “StrucSoft’s MWF has provided a one-stop shop solution for us. From the start of design all the way through to manufacturing, we can easily frame models and export to our machines”.

CSG is currently using two Howick roll forming machines, one for rolling 3 5/8” and the other for 6” members in a variety of gauges. Steel is then custom cut at their Baton Rouge factory, sheathed on one side, packed and then delivered to the job site for quick assembly.

By fabricating custom-made steel components to exact measurements (including dimples, swages, cut outs and more), CSG can screw together, and erect pre-assembled panels much faster than before when they were assembling individual members. Service holes can also be created to allow ease of other trades to run wiring through the metal stud framing.

Not only that but, CSG are able to produce the same structure built in hot rolled steel in light gauge steel for a fraction of the cost. This early adoption of LGS rolling has set CSG apart from other builders in their area who are using solely hot rolled steel. In fact, they’re able to design, manufacture and then erect a building in a shorter time frame and with a lower cost to the client than other traditional builders.

How did MWF help CSG’s workflow?

- Design to production time has significantly decreased

- Greater precision in construction coordination between multidisciplinary teams

- Increased productivity from project to project by reusing templates and setups

- Construction documentation and custom outputs are easy to understand allowing a faster and simpler manufacturing process

- Better communication across all platforms

- The process of LGS rolling has helped CSG maintain a workforce in the manufacturing plant

qweqwe Going forth, CSG is looking to add MWF Panel Stacker to their MWF Advanced Metal suite in order to optimize and stack LGS bundles according to how they will be unloaded and handled on site.

Welcome to the #MWF team, Construction Services Group (CSG)!

For more information about our products and/or services visit our website, email info@strucsoftsolutions.com or call us at 514-538-6862.