Here at StrucSoft Solutions, we work with clients across the globe to provide them with market leading wood and steel framing solutions, while at the same time gaining great insight into the various regulations and building types specified by each region.

As many of you may know, StrucSoft set down its roots first in Montreal, Canada, and more recently in Liverpool, UK. Today, I want to have a look at how construction differs in the regions of our two offices with some insights from our technical staff. Let’s delve into the differences on each side of the Atlantic. Why are there different construction types and building processes? Are new construction types narrowing the gap?

Zoning and Building Types

Let’s begin by having a look at European and North American building histories.

European cities are generally much older with a more concentrated population. As a result of this you are likely to see districts of mixed-use buildings, narrower streets, and enclosed squares for social gatherings. Concrete and masonry were widely used for housing across Europe.

With an extensive landmass across North America, you are more likely to find residential and commercial districts separate from each other with wider roads. Due to the vast forests across the US and Canada, wood framing for housing has been a popular choice for centuries and retains its popularity due to price and building speed. However, these traditions are starting to change as construction is being brought off-site and into the factory – also meaning that residential units are taking advantage of steel framing.

Building Regulations

An interesting similarity between North America and Europe is that both frameworks for construction management originated in the UK. Aside from that, the building codes for both continents have key differences in both standards and implementation.

The European Union implements a regulatory framework for all its member states including technical standards, health and safety, and the right to free movement for workers and construction products. These standards must be adopted by all member states, however each country has its own set of regulations that must work within the EU framework.

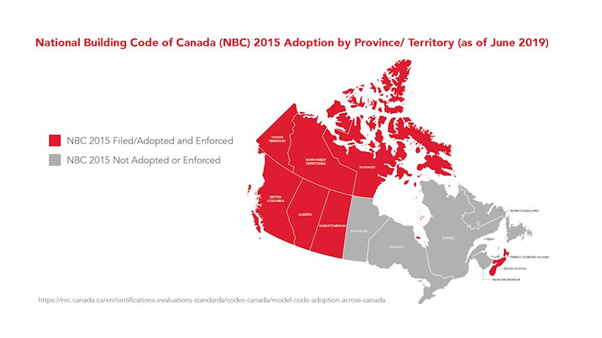

The USA and Canada on the other hand each have a national code, however it is not adopted by all states/provinces or is only partially adopted. For example, the ational building code of Canada (NBC) has not been adopted by provinces such as Ontario, Québec, and Newfoundland.

United States building regulations are more complex; The International Code Council Manages 15 different building codes including the International Building Code (IBC). The IBC is used as a base code by most of the US and some other countries including Abu Dhabi and Columbia. Each state adopts some or all the 15 ICC codes. This is sometimes due to geographical differentials (earthquake zones which have a different code for instance). Older versions of these codes are being used in Texas and Indiana. As of right now, seven states do not use any form of the two main codes at all (IBC and IRC). For example, Chicago has its own set of building codes.

Standards in the design process

There are a few differences in the North American and European design process, most obviously the difference in units– this has been the cause for many groans among our technical team!

The US has an extra measurement for steel framing know as a gauge. Gauges specify the grade of the steel and can be converted from the regular ml measurement. Design projects in the USA generally lean towards wood framing more often and in some parts of the US, adverse weather conditions must also be considered.

This makes inline wood or light gauge steel framing a popular choice. Additionally, a notable difference in the construction process is the responsibilities of an engineer-structural calculations from a UK engineer can be taken as guidelines whereas in the US the engineer has to approve building plans by law.

Sustainability

Climate change has kick started a revolution of new and more sustainable construction methods. The USA started to drift away from traditional wood frame construction to lightweight steel framing to stop forest depreciation. Metal framing is slowly becoming more popular as it removes the risk of root and insect infestation. Industry professionals are looking at new ways to lessen a new building’s reliance on mechanical ventilation using climate-responsive material and radiant heating and cooling systems.

With a more temperate climate, Europe generally has a lower energy consumption per building, however there is always room for improvement. Modern European construction focuses on low carbon output and airtight ways of building with recycled insulation and framing techniques – all seen in offsite construction.

Prefab Construction

Emerging technologies are blurring the lines between continents particularly in prefab construction.

This system was first adopted in Europe with North America not far behind. Prefab construction maximizes site functionality which was an immediate need in parts of Europe but with rising materials costs and developing cities the market in North America now has a much greater need for this solution.

The prefab construction system includes volumetric design where a whole room or unit is made in the factory and non-volumetric or component design where walls and floors are made as panels and then assembled on site. Both solutions offer a plethora of ways to cut down building time, create jobs, and increase sustainability.

Buildings types using offsite in North America can include hotels, dormitories, or healthcare buildings, although many smart housing systems for cities are in development. In Europe, modular construction is now at the forefront of radical design with it featuring in many award-winning buildings. StrucSoft’s star solution MWF, is used in both continents as the Revit framing software of choice for its cutting-edge automation paired with the streamlined planning and collaboration provided in the Revit environment. Due to its versatility, MWF can be strategically applied in various stages of the design process.

So, enough from me – let me know what you think in the comments. What are your experiences with cross-continental design?

For more information on our products or design services, visit strucsoftsolutions.com or email us at info@strucsoftsolutions.com.

Get started with your free trial now

Automate design and fabrication with the industry's most comprehensive Revit® framing software.