Offsite, prefabrication and modular construction—are they one and the same? All three terms are used fairly interchangeably in the construction industry. Let’s find out some key distinctions that set them apart in this article.

Offsite Construction

The NIBS defines offsite construction as “the planning, design, fabrication, and assembly of building elements at a location other than their final installed location”. In this process completed sections of the building or individual components are transported on-site and rapidly assembled, the main advantages being enhanced quality control and reduced timelines.

Offsite construction is an umbrella term that covers both modular construction and prefabrication depending upon the context, as it can mean entire pre-built modules, or individual units (such as walls, floors and roofs) that are installed on-site.

Is offsite construction the future of the industry? Read this blog to learn more

Modular Construction

The MBI defines modular construction as “a process in which a building is constructed off-site, under controlled plant conditions using the same materials and designing to the same codes and standards as conventionally built facilities”. The first part may sound awfully similar to the various definitions of offsite construction that are available online.

Modular construction as a term however is typically used for projects that require a high degree of repetition or standardization, including multi unit residential buildings, hotels, student housing.

As the name suggests, this construction method involves building entire ‘modules’, which are completed units that may also include finished interior and exterior walls, floors and other components, that are stacked like lego blocks, or jenga blocks.

We may come across terms like volumetric modular, meaning three dimensional modules that are finished and ready to be installed, as mentioned above. It is also used to distinguish from ‘panelized construction’, where individual sections such as wall panels and floors are fitted together on-site.

Many of us will use modular construction and prefabrication synonymously. However in this scenario, it would imply panelized construction or a ‘kit of parts’, that is prefabricated off-site, as opposed to a three dimensional module. We hope that wasn’t too confusing.

Prefabrication

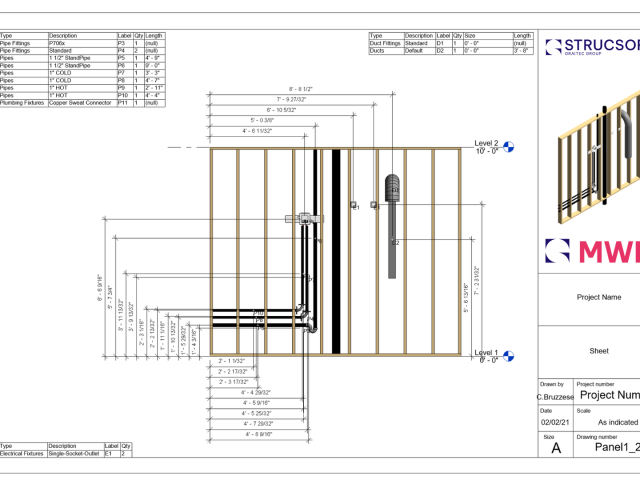

Prefabrication (or prefab) and modular can be used synonymously. However this method of offsite construction may generally refer to a 2D ‘kit of parts’, or components that are manufactured individually and installed on-site – such as wall panels, floors, trusses. Contrast this with modular construction, a term that would lean more towards three dimensional modules, finishings included.

Keeping these distinctions aside, the terms ”prefabrication’, ‘modular’ or ‘offsite construction’ ultimately point to the same direction. All roads lead to Rome, and Rome in this case is a shift in the way buildings are built—the factory, instead of the construction site.

Discover our solutions for offsite builders are designed to accelerate your modelling and manufacturing workflows

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com