For years, many construction companies were less receptive to offsite construction due to its association with having to sacrifice style for functionality. Recently, however, more are learning that offsite methods can benefit from speedier construction without restricting innovation in design thanks to technological advances in wood and light gauge steel framing, as well as advanced framing software.

The construction industry has been growing exponentially, with an estimated reach of global output to $12.9 trillion by end of 20221. This tremendous growth has opened opportunities for innovations and the disruption of traditional construction methods. New technologies including BIM software and data eco systems, augmented realities, precision led wood and steel framing machines have led to a more streamlined construction process with a higher output than ever seen before.

Why is offsite construction the future of the industry?

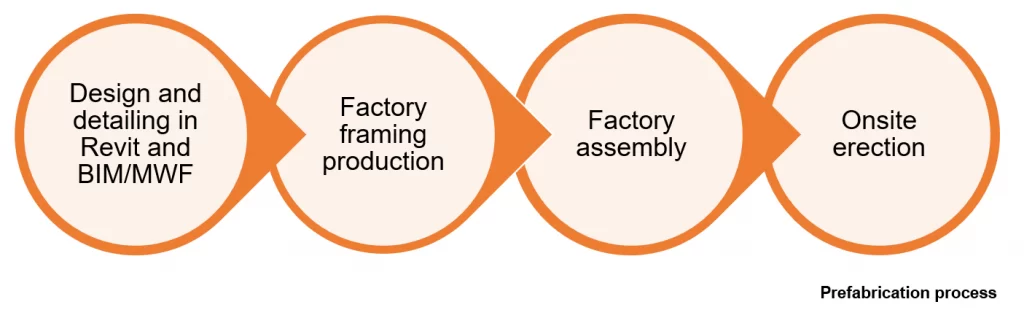

Modular, prefab and offsite construction using wood or light gauge steel framing may not be a new idea but with improved developments in framing and design software, including precision led framing machines, building design software has automated and reinvented the technique of off-site construction.

Additionally, by moving a large proportion of the work from an open setting with limited working hours into a controlled indoor facility with 24/7 production potential, offsite construction offers various benefits:

- Faster process

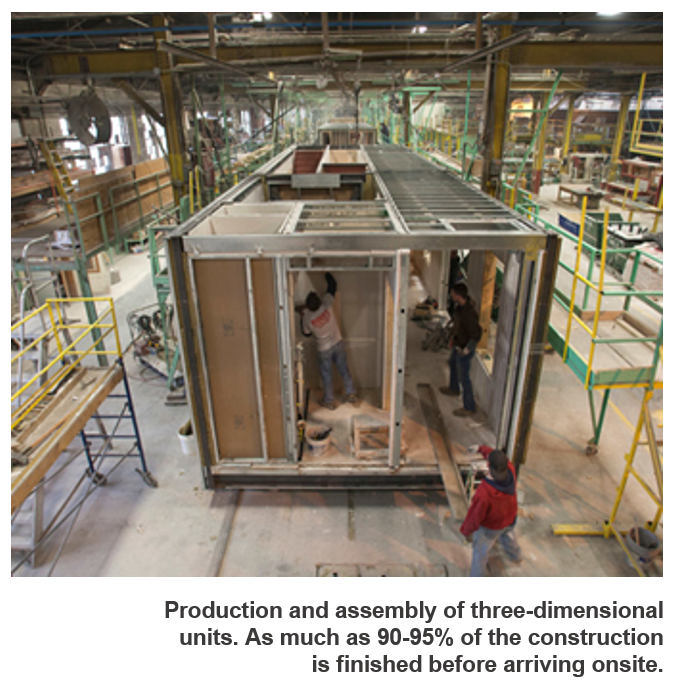

As offsite construction is factory based, the on-site construction time is reduced drastically. Weather factors like rain, snow and winds no longer hamper the process and panelized framing can be done for walls with their respective wood or metal studs, floors, roof panels – each having all members cut and fixed together, then delivered to site. This flexibility with delivery makes panelized framing a strong contender for sites with tight or restricted access. Additionally, as the product has already been pre-assembled, installation can begin immediately once brought to site.

- Less waste/ eco friendly

Due to the higher control of the construction process and more precision, construction waste and worker’s carbon footprint is decreased. Not only that but, due to the well designed, modular nature of offsite construction methods, re-usability of building materials is possible. In some cases, units, rooms or even entire floors could be preserved and re-purposed, ultimately reducing potential landfill waste.

- Lower cost

The controlled, weatherproof workplace allows for lean manufacturing. Which means more savings that can be reinvested or given to customers.

- Safer and more stability

Since most of the building is created in a factory, workers do not have to worry about seasonal work. This in turn creates a more stable environment and steady wages, making construction jobs more desirable. Additionally, in a controlled factory environment, higher health safety measures can be implemented and building indoors is far less subject to the risks—legal and financial—inherent with subcontractors and the number of site accidents.

- Higher quality control

Thanks to a controlled environment and regular quality checks, a higher quality assurance system can be put in place in the design and factory. Materials used are all machine produced and have little to no human interference, unlike traditional construction. With framing software like Revit and MWF, every inch of the project can be visualized and checked for errors before production. Roll formers are able to input this information, produce accurate framing and sheeting with insulation and finally have the product ready for onsite assembly. This simple workflow allows companies to enforce higher control over the end product.

Adopting offsite construction

Certainly, some challenges remain. Individuals often associate offsite construction with low quality, uniformed housing that leaves little to be customized. Additionally, robotics and 3D printing need more investment and R&D before they can realize their full potential and workers require a new set of skills.

quality, uniformed housing that leaves little to be customized. Additionally, robotics and 3D printing need more investment and R&D before they can realize their full potential and workers require a new set of skills.

Nevertheless, the switch has begun. Companies that adopt offsite methods and quickly consolidate their workforce and technology, will enjoy a competitive advantage in the future.

For more information on our products or design services, visit strucsoftsolutions.com, email us at info@strucSoftsolutions.com or call us at 514-538-6862

Automate your workflows with our Revit framing software for offsite builders. Learn more.