How to choose between metal framing studs vs wood framing studs?

Light gauge steel and wood still remain the most commonly used building materials to frame walls in the world. Metal framing is cold formed to create long, thin sheets capable of holding heavy loads. Wood is more readily available and assembled via stick framing. Learn more about the differences between metal framing vs wood framing in this blog.

In this blog post we will focus on the differences between metal studs, (or steel studs – we’ll use the term interchangeably) and wood studs – so you can choose the right ones for your next project.

Read more about the benefits of each building material below.

Whether you are building a steel frame or a wood frame, the feasibility of using either building material depends heavily on the size of the home, current price of materials, the team you hire and what light gauge steel framing software or wood framing software you use (assuming you are using one). Nevertheless, builders tend to prefer one over the other. Why is that?

In the past, wood studs were used around the world for almost all construction projects. Nowadays wood framing is predominately used for residential buildings especially in North America and Europe. On the other hand, according to the Steel Framing Alliance (SFA) more than 40% of commercial buildings are constructed using metal framing.

Below you’ll find pros and cons for each material, helping you decide what it best for you.

- Pricing

Wood studs are cheaper and readily available at a local hardware store. The same cannot be said about light gauge steel studs. Pricing for steel is typically 3%-15% more expensive than wood and it is harder to find.

When comparing pricing, insurance and safety expenses must also be considered. Cold-formed steel is non-combustible due to which risk insurance prices will be lower for projects using light gauge steel framing. Wood on the other hand offers lower labor costs since a greater number of professionals have experience working with wood compared to metal. - Durability

Steel’s adaptable nature helps it withstand high winds, earthquakes and other stressors. Not only that but light gauge steel is impervious to the elements (moisture, winds, insects) and is not subject to rot – which in turn keep your structure as straight as the day it was built. Such a statement cannot be said about wood.

Though wood studs are very strong and can hold more weight than steel, the lifespan of wooden studs is considerably lower than light gauge steel studs. - Weight

It can be said that wood studs are stronger than light gauge steel because of the sheer weight and density of this material.

However, metal studs boast a better strength to weight ratio. Unlike wood studs, steel frame is much lighter and easier to use and as a result they are easier to transport, manipulate and also install. - Insulation

Compared to wood, steel has a much lower insulating capacity. Because of this, cooling and heating costs can become quite expensive when using steel framing.

Wood on the other hand is a natural insulator due to the air pockets present in their very cellular structure. - Maintenance

Wood framing can be subject to rot and moisture infiltration. Aging wood-framed structures are prone to suffering insect damage and have to be replaced over time. While metal framing has the potential for rust in similar conditions, the overall maintenance costs of steel framing will be less than their counterpart. - Eco-Friendly

Wood requires less energy to produce. With that said, constructing with wood can help combat climate change, provided that an equal amount of new trees are planted in order to convert carbon dioxide into oxygen (photosynthesis). Steel on the other hand is now 100% recyclable and does not emit Volatile Organic Compounds (VOCs) that can be found in wood. - Waste

When using a CNC machine, both materials are cut to precision and have little to no waste. However, steel is cleaner, scrap rates are under 2% and it does not emit sawdust – a cleaner job site happens to another benefit of using metal studs. - Style flexibility

When thinking about the project that you are working on, one must consider if you’re mounting a TV, need to have a load bearing wall or add a door for example. While metal studs have their advantages when it comes to strength, it is easier to perform simple tasks such as nailing a door, with a material like wood – the same cannot be said for steel.Finally while wood is less expensive, eco-friendly and more widely used in residential buildings and demands no learning curve, light gauge steel offers a lighter, more malleable product that will stand the test of time. Which one is better or smarter?

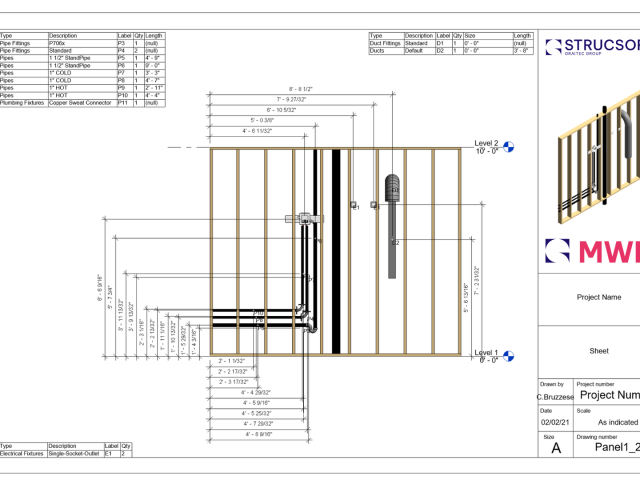

Framing Software like MWF Pro Metal and MWF Pro Wood can help alleviate some misconceptions of each building material and will help you build more quickly and efficiently than ever before. Limiting waste, time and money across all projects.

Need more information? Get in touch to learn more about how MWF (Metal Wood Framer) can help you with your next framing project!

For more information on our products or design services, visit strucsoftsolutions.com/products, email us at info@strucSoftsolutions.com or call us at 514-538-6862. StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit® based wood and steel framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit® based wood and steel framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.