Have you ever heard that modular construction is a magic bullet for the housing crisis? Or that modular is just a fleeting trend in the dynamic world of construction?

In this blog, we’ll look at some common myths and misconceptions that surround modular construction, and attempt to debunk them. Let’s get started.

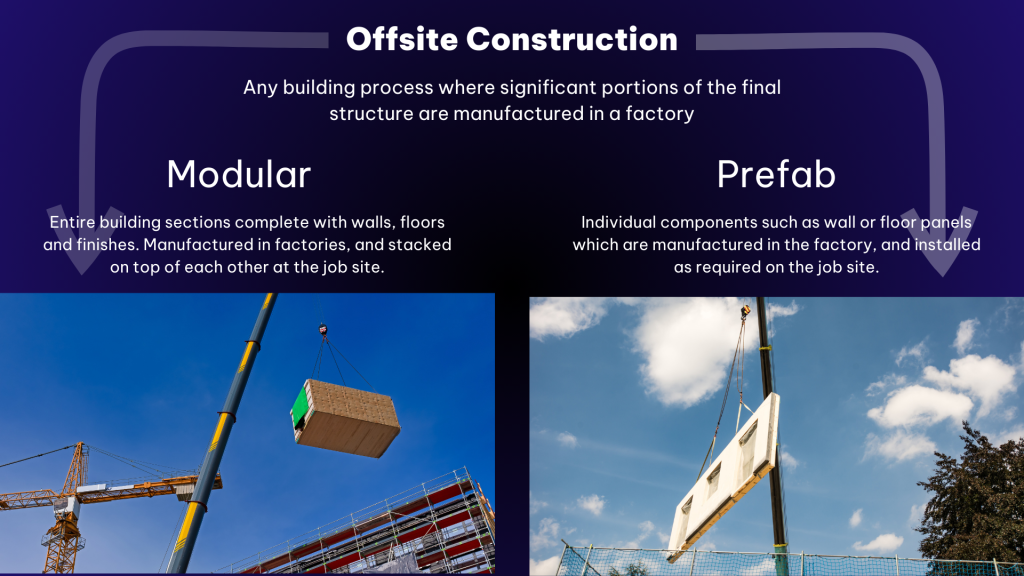

Modular, Prefab and Offsite Are Synonyms

There is a common misconception that modular, prefab (prefabricated) and offsite construction mean the same thing.

Offsite construction is a broad term that refers to any construction process where significant portions of the final structure are manufactured away from the actual construction site in a controlled factory setting.

Modular construction occurs when entire sections of a building, complete with electrical finishes, plumbing and more, are manufactured in a factory and brought on-site for assembly.

Prefabrication refers to the process of manufacturing individual components as opposed to entire modules in a factory. This means a building can be built on-site with traditional methods, while still incorporating some prefabricated elements such as wall and floor panels.

Learn more about the differences between the three terms in this blog post.

Modular Is an Unproven Construction Method

Modular risks being perceived as an unproven construction method, mainly due to its newness. In its current iteration, modular construction has only been around for a few decades, in contrast with traditional methods which have been around for centuries if not thousands of years.

The end-user may view modular construction with skepticism, either due to a lack of familiarity, or being naturally biased toward traditional construction methods.

On the industry side, established construction companies may be hesitant to shift to modular methods due to concerns about build quality, design flexibility or quite simply, the initial investment required to make the shift.

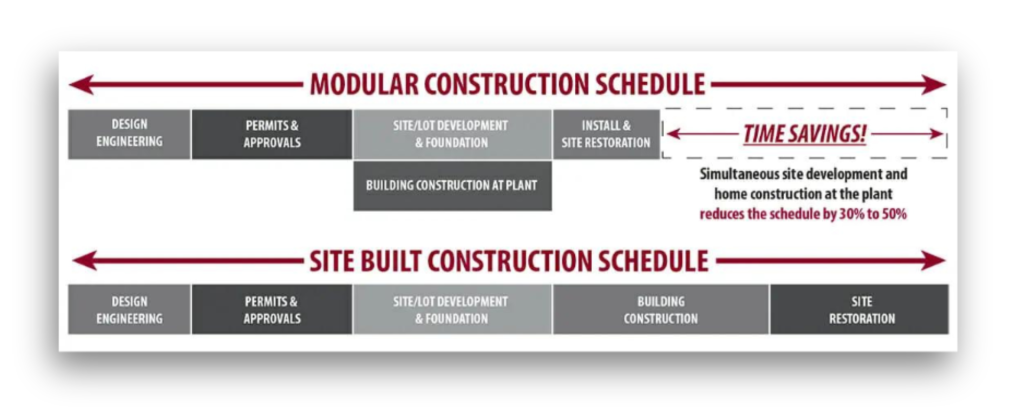

As a result of standardized and controlled processes, the modular construction process is 30-50% faster compared to traditional forms of construction, translating to significantly faster occupancy rates compared to traditional projects.

The modular construction movement has been on a steady rise in recent years, in-sync with technological advancements that are being made on the software side. The more comprehensive and demanding 3D modeling becomes, the more expectations projects place on the digital tools they use to design their structures.

StrucSoft’s framing software such as MWF Pro Metal and MWF Pro Wood, are Revit based solution used by modular builders to automate the modeling of their project’s wood and light gauge steel framing. It is also capable of exporting project data to CNC machinery, making it easier to fabricate Revit designs.

Modular Homes are Low Quality

There are many reasons why this misconception may arise. A common one is associating modular homes with mobile homes. Both are manufactured off-site in a factory setting, further adding to the confusion.

USFrameFactory‘s co-founder Tiago Atwi sheds some more light on the differences between mobile homes, and modular homes:

“…Mobile homes are relatively cheaper, and that reflects in their build quality. For example, they are made using thin drywall which affects durability of the building and results in poorer acoustics. Mobile homes are made to be transported on a road and set up with a truck. They are always 1 story tall, and importantly, they can very easily split in half if not assembled correctly.

In contrast, modular homes are made in a controlled factory setting. They are typically built using higher quality materials and drywall. They require relatively specialized transportation to deliver them on-site. Because they are designed to be stacked on top of each other, it also requires the use of cranes to hoist them in place. While there is no such thing as a “Modular Building Code”, modular construction tends to follow local building codes, and the IBC (international building code)”.

Modular Construction Is Always Cheaper

There is a common and well-founded belief that anything mass-produced in a factory setting is cheaper, due to economies of scale and standardized processes. In modular construction, economies of scale indeed reduce costs, particularly for projects with repetitive designs, as opposed to custom one-off projects.

While modular construction projects are typically cheaper than traditional site-built structures, there are certain factors that may give the impression that the cost savings aren’t as substantial as expected:

Design complexity: Most modular builders, and more so on the residential side, will have a ‘catalog’ of modular building designs that the client can choose from. These

Transportation and Assembly Costs: Unlike traditional construction, modular buildings require specialized transport to ensure the finished product is delivered safely to the construction site. Costs can vary depending on the job site’s location, and the complexity involved in getting there. Secondly, assembling the structure on-site requires the use of cranes, which can also potentially offset cost savings.

Specialized Talent: Modular construction is an innovative building method that may require design and construction teams to alter the way they work. As the majority of the construction process takes place inside a factory, teams that are more familiar with traditional construction methods may need to re-skill, which in the mid-short run can add to the costs of construction.

Modular construction is on average cheaper than traditional construction, which by itself may not be a good-enough reason for builders or clients to shift to modular construction. When paired with its high speed of construction and build quality, that’s where modular construction hits the sweet spot.

Modular Homes Will Fix the Housing Crisis

Many view modular construction as the ultimate solution for addressing the housing crisis in Canada or the United States. Given the speed of construction and cost savings offered by modular methods, this comes as no surprise.

However this oversimplifies what is otherwise a multifaceted issue. Modular construction is a method of delivering housing quickly with potential cost savings. This construction method doesn’t directly address other critical aspects of the housing issue, such as land availability, zoning laws, and other socioeconomic factors.

As Tiao Atwi explains “…particularly in the United States, zoning laws are among the main factors behind the expensive housing rates in large metropolitan areas like Chicago, San Francisco, and Los Angeles.

The San Francisco-Oakland area for example, is dominated by single-family zoning. Zoning regulations are controlled by neighborhood boards and small municipalities, which regularly vote against updates that would allow the development of affordable housing.

The opposition to affordable housing stems from a belief that large complexes will lower the value of single-house lots. So, despite developers offering significant cost savings with modular construction, local laws prevent them from acquiring the land in the first place.

In the last 40 years in the United States, the median purchasing power of family salaries hasn’t kept up with inflation and the increased cost of living. The Pew Research Center defines purchasing power as “real wages,” which they report has not increased in 45 years for median-income earners.

The definition of affordability is relative, and in this case, housing prices have been increasing over time while the average family’s purchasing power hasn’t.

Taking all these factors into consideration, builders and developers shouldn’t be discouraged and should still strive to increase the viability of modular construction in the housing market.

There are creative ways around zoning, such as offering ADUs (accessory dwelling unit) and repurposing abandoned buildings such as malls, and industrial areas.

In terms of political action, they should consider political lobbying to combat zoning and socioeconomic factors. Potentially, they could even lobby for more public transportation to rapidly connect affordable housing developments with economic districts.”

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com