Did you know, between 10% and 25% of project costs are lost through construction errors? That’s a lot of money!

Fear not, the answer could very well lie in purchasing and using high-quality building design software.

In light of that, we’re going to explore precisely how building design software can help reduce construction errors and consequently boost your bottom line.

There’s lots to cover, so let’s dive in!

1. Avoid Communication Problems

In 2018 alone, as much as over $31 billion was lost in the construction industry due to data mismanagement and misunderstandings! The moral of the story: Tighten up your communication throughout the entirety of your construction project.

When you use software that enables you to create, manage, and store all your architectural, structural, and manufacturing data conveniently in one place, you’ll be amazed at how much easier it is to communicate with the rest of your team.

With better communication, you’ll nip any potential misunderstandings that could translate into construction errors in the bud before they become a costly problem.

Here are just a few of the ways such building design software can enhance communication on your construction project:

Plug Information Gaps

As you already know, it often takes huge teams to plan and execute large-scale construction projects. With so many people on board, you’ll inevitably be working with people boasting varying levels of skill, experience, and knowledge of the kinds of work you’re completing.

As such, the last thing you want is to assume everyone possesses the necessary know-how to get the job done to a satisfactory standard.

This is why providing relevant resources or training that’s easily accessible is essential for plugging any information gaps. This helps to ensure everyone’s on the same page from the get-go.

Make Sure Everyone Has Access to the Latest Docs

Construction projects evolve, and, as such, so do the docs, drawings, and schedules that accompany them. With so many moving parts, it’s no wonder communication issues frequently arise.

Again, this is why everyone on your team must have access to the latest versions of any documents so that everyone’s working from the same plans to reach the same end goal.

Make Job Roles Clear

Never assume that everyone on and off-site has a clear idea of their job roles and responsibilities. It would help if you made clear to everyone who’s responsible for handling specific problems at various stages of the construction process. That way, everyone knows who needs to pick up the baton to ensure nothing slips through the cracks.

For instance, it’s not uncommon for simple issues like who’s supposed to document deliveries to get out of hand and lead to more costly problems. The same goes for higher-tier issues, like confusion over the designated point of contact for subcontractors.

If things like this aren’t understood from the beginning, it’s inevitable confusion will arise, which massively increases the likelihood of mistakes occurring.

2. Visualize the Project Better

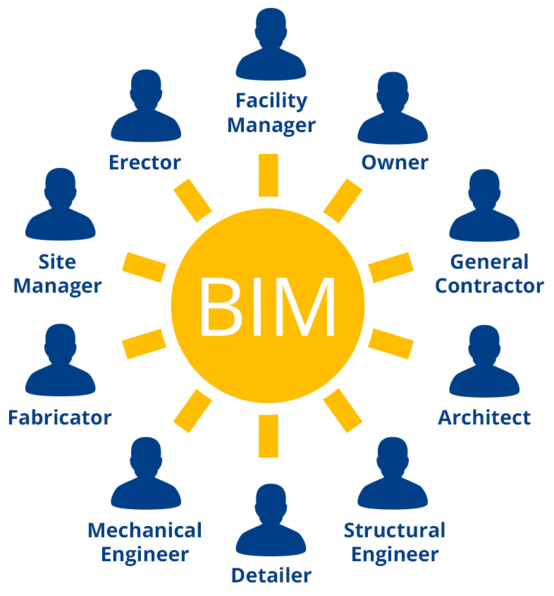

With any construction project, it’s imperative to visualize and coordinate the design from the outset thoroughly. Failure to do so can result in significant design and safety errors. This is where harnessing the power of building information modeling (BIM) is worth its weight in gold. << Click here to learn how to bring safety to the construction site using revit framing software >>

This kind of software empowers everyone on your construction team to see and update the plans in real-time. It also makes it easier for team members to provide feedback throughout the entire design process to ensure everything stays on the right track.

Gone are the days where contractors had to work from an elaborate paper-based architectural plan. Instead, from the convenience of a smartphone, your construction team can analyze and implement architectural plans from their pocket, anywhere, anytime! Never before has it been easier to access and work with the most up to date plans at your fingertips. Needless to say, this goes a long way to minimizing construction errors later down the line.

3. Set Quality Standards

In the construction game, the last thing you want is to employ a ‘go with the flow’ attitude – this never bodes well. Instead, if you want to achieve the best of the best and keep mistakes to a minimum, you need a set of systematic standards in place that need to apply to all the processes, workflows, and equipment adopted throughout the project.

This is where building a framework for quality assurance and quality control measures come in handy. Again, with the help of a decent building design software package, you’ll get access to plenty of templates to help institute this kind of standardization throughout your construction projects.

4. Learn From Mistakes

If the unfortunate happens and a mistake does occur, you need to document it and learn from it. This means documenting the issue and coupling it with an explanation as to what happened.

This is where field collaboration software comes in useful because you can embed photos into the sheets. Within seconds you can update the team on any issues that occurred and advise on preventing the same problem from happening again.

Are You Ready to Start Using Building Design Software?

We hope having read this article, you now have a better idea of how you can use building design software to reduce construction errors on your next project.

If this is something you’re interested in, please feel free to get in contact, and we’ll talk you through some of our best software – most notably our MWF Pro Metal, MWF Pro Wood, and CNC modules.

For more information on our products or design services, visit strucsoftsolutions.com or email us at info@strucsoftsolutions.com.{{cta(‘3376e831-dc64-4659-90ca-0292502bc61f’,’justifycenter’)}}

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.