For many years now, the construction industry has been undergoing a steady increase in the implementation of digital technologies, such as cloud production management software, drones, building information modeling (BIM), virtual and augmented reality, 3D printing, artificial intelligence and much more.

But why is this important, and what does this mean for the future of the construction industry? In this article we’ll learn how these technologies are revolutionizing the offsite construction sector.

Due to an ample supply of human capital and its unique functional approach, the AEC industry has traditionally been in a state where the need to adopt newer technologies was not as urgent compared to other sectors.

Fast forward to 2010-2020s, the sheer magnitude of technological advances began to be noticed by all sectors to varying degrees, including the AEC industry which has begun reaping the rewards offered by digital technologies. The offsite construction sector in particular, which has been around for centuries and more notably during the post World War period, has gained a lot from technological applications. Let’s take a look at some of them below.

Digital Technologies Impacting Offsite Construction:

- The Cloud as it applies to Production Management

- Drones – surveying, 3D map generation.

- Building Information Modeling (BIM) Software

- Virtual and Augmented Reality (VR, AR)

- 3D Printing

- Artificial Intelligence

1. Cloud Production Management Applications

Digital apps are becoming a greater norm in construction than they ever have been in the past. The increased portability of tablets and smartphones allows for greater communication and collaboration especially considering one has the added ability to work from anywhere at anytime.

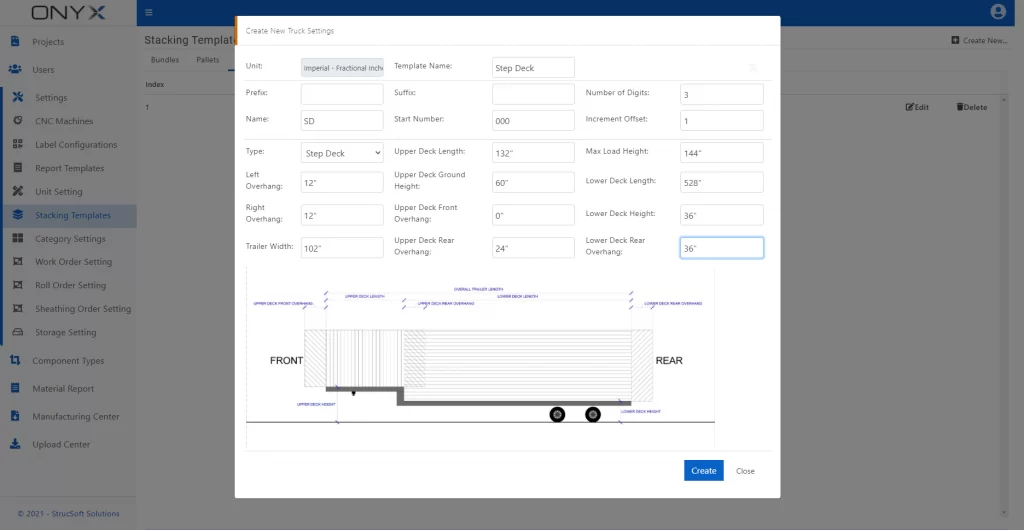

Take our cloud production management solution, Onyx. Using Onyx, users are able to access multiple projects through any web enabled device for easy sequencing, scheduling, editing and CNC output with ever having to download the Revit file. Updates to your models can be made in real time and data is instantly stored for when production begins – allowing for full transparency on the shop floor and assembly site.

Cloud production applications are helping construction companies gather more accurate and higher quality data from the jobsite. Integrating this type of technology into your current processes is simple and provides major benefits, including:

- Time savings

Weather factors like rain, snow and winds no longer hamper the process and panelized framing can be done for walls with their respective wood or metal studs, floors, roof panels – each having all members cut and fixed together, then delivered to site.

- Enhanced workflows

Thanks to a controlled environment and regular quality checks, a higher quality assurance system can be put in place in the design and factory. Materials used are all machine produced and have little to no human interference, unlike traditional construction - Improved safety for employees

Since most of the building is created in a factory, workers do not have to worry about seasonal work which create a more stable environment (which means steady wages!). Not only that but, higher health safety measures can be implemented and building indoors is far less subject to the risks—legal and financial—inherent with onsite accidents.

- Automatic reporting

Easily customize reports based on the project scope, modify and continue on. Within one app, users can keep track of multiple projects and adjust members, operations and more, onsite, in a matter of seconds.

2. Drones

Drones have started to become more widely used in the construction sector, notably for their surveying and 3D map generation capabilities. They can conduct site surveys more quickly and accurately than a crew on the ground and are cheaper than aerial imaging. Another benefit of using drones is the ability to inspect hard to reach places and to do so safely. You can also use them to remotely monitor installation progress on a job site, instead of having to be there personally – thereby allowing inspection of multiple projects from a singular location.

3. Building Information Modeling (BIM) Software

BIM software combines multi-disciplinary data to create detailed digital representations of projects that can be managed on a singular platform for real-time collaboration in a shared environment.

The use of BIM provides space for better collaboration since each member of the project and/or expert can add their piece to the same model. This way, the model evolves immediately as people contribute, streamlining the process and increasing efficiency. BIM also helps early in the design and planning stages of a project, by automating clash detection, providing changes and the ability to make modifications before output.

clash detection, providing changes and the ability to make modifications before output.

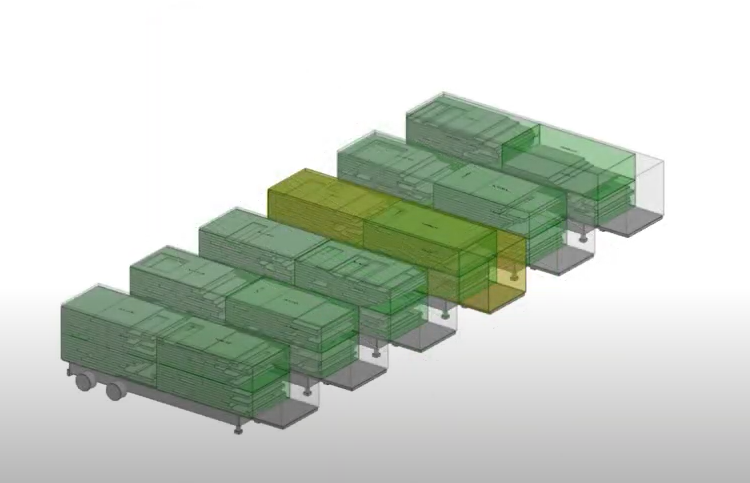

Prefabricated and modular options are becoming the norm for building. By moving a large proportion of the work from an open setting with limited working hours into a controlled indoor facility with 24/7 production potential, BIM software combined with offsite construction offers various management benefits such as higher levels of detail, precision, stability, quality control and much more.

<<Read more about the Benefits of BIM in Construction Management Here>>

4. Virtual Reality

Virtual reality technology is often used in conjunction with BIM to help better understand complex projects. Think of it…you create a building design and then use VR to actually walk around it before breaking ground? Pretty cool, right? This will give your team, or the client, an even more realistic idea of what the project will look like once completed. In some cases this extends to full furnishings of buildings as well! Having a more complete grasp on the project before it begins gives you the opportunity to avoid big changes and expensive change orders mid-way through.

5. 3D Printing

Gone are the days of waiting for shipping delays! 3D printing as a construction technology has the potential to change material sourcing. For prefabrication, materials for a project can be printed and then transported to the job site, completely ready for use – allowing you to get materials faster and to be able to streamline processes by removing extra steps in the middle.

3D printing makes it possible to print materials right on site, reducing waste and further saving on transportation and storage costs. However, one of the current challenges with adoption of this technology is limitations with mass production. It can also be time consuming and although some 3D printers can produce on a larger scale, they are expensive. All that to say – it’s not for everyone, but it’s only a matter of time until the technology becomes more readily available and easy to use.

6. Artificial Intelligence

For years, artificial intelligence (AI) has provided benefits to construction projects through increased safety, improving workflows, and the ability to get jobs done faster and better. Companies that are more comfortable with the technology have started to build out their own AI programs to help with internal decision-making processes and operations. While other firms are relying on third parties to audit their current practices and identify opportunities for AI and/or machine learning implementation within their current offsite practices.

What Does This Mean for the Future of Digital Technology in Offsite Construction?

While all these developments are helping the engineering and construction industry realize impressive productivity gains, we still have work to do the meet the enormous potential of digital technology in offsite construction.

Offsite construction can alleviate many issues. Taking construction offsite and into a manufacturing environment opens the door to standardized designs, streamlined processes and automated production techniques. Combine that with digital technology like Onyx… it’s a no brainer.

For more information on our products or design services, visit strucsoftsolutions.com/products, email us at info@strucSoftsolutions.com or call us at 514-538-6862.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.