From condominiums to offices, the modular construction industry is taking the construction world by storm!

Modular construction is the process where sections of a building are constructed offsite inside a controlled environment, transported and then joined together at the build location.

Keep on reading to find out what modular construction is all about.

What is Modular construction?

Modular (or prefab) construction is not a new concept. However due to technological improvements, economic demands, and shifts in mind-sets means that it is attracting massive amounts of interest in the construction industry.

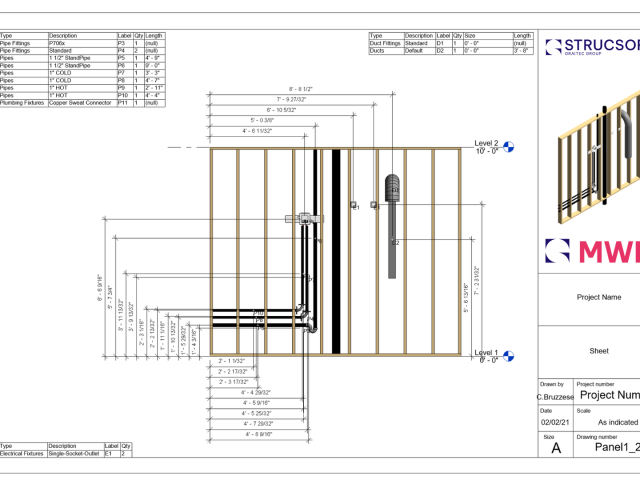

Modular structures consist of multiple parts that are prefabricated offsite in a factory controlled environment and then brought on-site either in ready to assemble parts or in a completed modules. Once they’re transported to the desired location, the parts are placed on a permanent foundation and assembled, adhering to local building codes.

Modular construction process:

1. Design approval adhering to local building codes by client

2. Production of components or modules

3. Transportation of modules

4. Installation

What are the benefits of building modular?

There are many benefits to building offsite including the “greener” aspect, time savings, cost savings and more. Keep on reading what each of these mean!

Ecofriendly:

The factory controlled process generates less waste and experts are able to plan their build better while completely minimizing the energy and resources used to demolish a structure or in order to build a new one. Here’s how:

- Less Material Waste:

When building in a factory, waste is eliminated by recycling materials, controlling inventory and protecting building materials. Builders are able to reduce the demand for raw materials and minimize the amount of energy expended to create a building. - No need to store materials:

When a site is tight on space, this causes clutter and will slow down work. By building the modules in a factory, construction sites can remain cleaner and safer, and provide more space to work and move around freely. - Reduces carbon footprint:

Producing buildings offsite will reduce carbon emissions that are often generated on large construction sites due to heavy foot traffic.

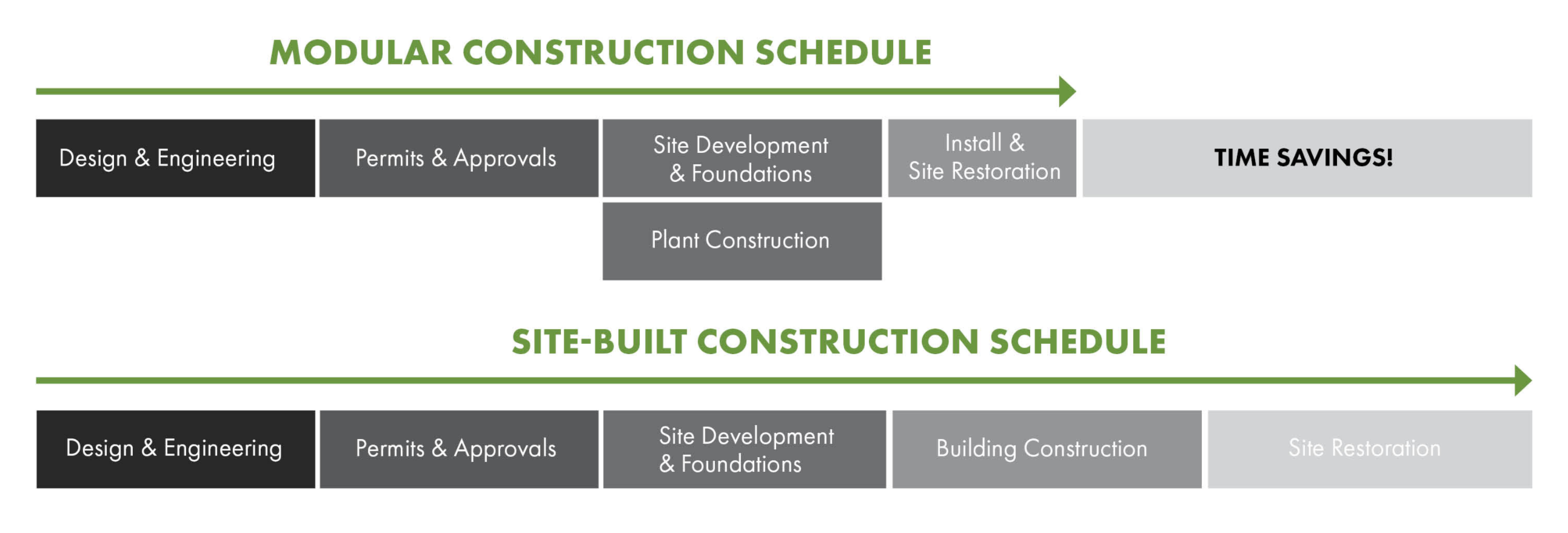

Time efficient:

The construction of modules occurs simultaneously with site work, allowing projects to be completed in half the time of traditional construction. Here’s why:

- No site disturbances

Because parts are being built in a indoor factory or warehouse, weather delays are something of the past. Workers no longer have to rely on the elements (i.e. rain, snow etc.,) in order to begin and continue their build. - Faster construction timeline:

Since the product has already been partly pre-assembled, installation can begin immediately once brought to site because the foundation has already been set.

Cheaper:

By moving a large proportion of the work from an open setting with limited working hours into a controlled indoor facility with 24/7 production potential, offsite construction is a cheaper building process. How it’s possible:

- Faster speed:

The single greatest cost saving aspect of modular construction is the speed with which the building can be finished. Modular construction can be up to 30% faster than traditional onsite construction. - Lower cost:

The controlled, weatherproof workplace allows for lean manufacturing. Which means more savings that can be reinvested or given to customers.

Smarter:

Modular buildings are built with the same materials and with the same building codes and as traditional construction. Once assembled, they are virtually indistinguishable from their onsite built counterparts. Here’s why:

- Safer:

The indoor construction environment reduces the risks of accidents and related liabilities for workers. - Better quality control:

Thanks to a controlled environment and regular quality checks, a higher quality assurance system can be put in place in the design and factory.

With all this said, companies that adopt offsite methods, quickly consolidate their workforce and technology, will enjoy a competitive advantage in the construction industry.

StrucSoft is thrilled to announce our new sponsorship with the Modular building Institute! To learn more about modular construction and the process, visit modular.org.

For more information on StrucSoft’s products or services, visit strucsoftsolutions.com, email us at info@strucSoftsolutions.com or call us at 514-538-6862