What is DfMA ?

DfMA stands for ‘Design for Manufacturing and Assembly’, a framework that focuses extensively on designing products that are easier to manufacture and assemble.

This design led process has been used since the 1980s to drive down overall costs of consumer appliances, computer hardware, automobiles and airplanes – products created from individually manufactured components, and assembled together in a factory setting.

Applied to the built environment, the building is viewed as a ‘product’, which can be split into modules. These modules are standardized, repeatable and interchangeable, similar to the examples above.

DfMA in the Built Environment

DfMA methodologies have been used to build residential and non-residential projects in North America, Europe and the United Kingdom, primarily by offsite and modular builders.

Cost reduction, improved manufacturing efficiency, and overall simplification of the building process are some recognized benefits of DfMA.

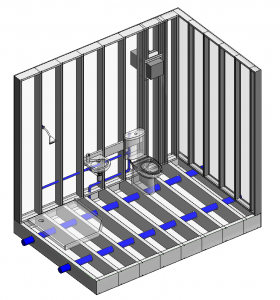

Within the offsite sector both residential and non-residential builders can use the DfMA methodology. In the case of a modular builder specializing in constructing bathroom pods, the DfMA process will involve creating a design that is optimized for repeatability.

In other words, the design will require using as few subcomponents or processes as necessary, thereby simplifying the overall complexity of building and assembling the product.

With such a standardized design, the same bathroom pod design can be used in various applications – a school, healthcare unit, or a multifamily residential complex.

Simplifying and standardizing the design will therefore result in reduced costs due to the elimination of excess components or processes, and consistent quality. Because the product is designed for ease of manufacture and assembly, there will be an increase in process efficiency, productivity and therefore time savings.

Light gauge steel and wood framing with DfMA

Designing and building the framing is an essential part of any construction project, forming the base upon which other building components will be attached to and integrated with, such as MEP systems.

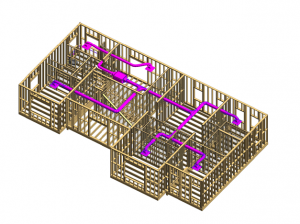

The MWF software enables DfMA workflows by facilitating the design, coordination, manufacturing and assembly of their light gauge steel or wood framing.

The framing is conceptualized and modeled in a 3D environment, allowing users to make key decisions around the design of their framing to improve manufacturability and assembly.

MWF allows users to automate the modeling of their framing, reducing manual and repetitive workflows and accelerating the modeling process.

Using a design-led approach such as DfMA naturally requires the establishment of a link between downstream contractors and design trades, which includes the identification and resolution of multidisciplinary clashes.

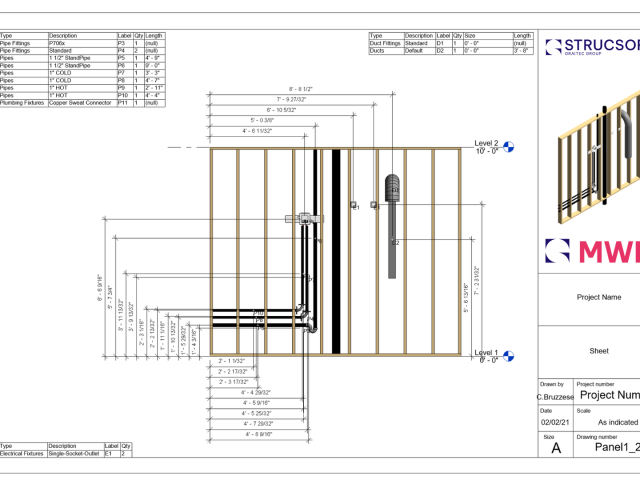

MWF improves coordination between architectural, structural and MEP models, ensuring that when the framing is manufactured, it is preconfigured to integrate with ductwork, piping and is structurally sound.

Models created in MWF contain data that is ready for manufacture. This data can be transferred to CNC and roll forming machinery, enabling a smooth transition from designing framing components virtually, to fabricating them on the shop floor.

Assembling the manufactured components is simplified with the generation construction documentation such as shop drawings, cut lists, BOMs.

MWF allows builders to create, coordinate, engineer and fabricate their woos and cold formed steel framing within the Autodesk Revit environment. With a toolset enabling workflow automation and seamless transitions from the screen to the shop floor, MWF is the complete software for the designer and manufacturer. Learn more about MWF here.

For more information on our products or design services, visit strucsoftsolutions.com, email us at info@strucSoftsolutions.com or call us at 514-538-6862

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.