Find out how PWI accelerated their production processes with CMS DSTV NC1 plugin for Autodesk Inventor

The Company: PWI

A family owned business now run by second generation descendants, PWI specializes in maximizing the productive capability of manufacturing spaces. The company achieves this by equipping manufacturing plants with overhead cranes, raised work platforms or mezzanines, and fall protection systems, all designed and manufactured in-house.

In addition to their core business, PWI has found success with branching off into the production of industrial stairways, bridge cranes and jib cranes.

How PWI Uses CMS for Inventor

Based in Nappanee, Indiana, PWI’s operating facility houses a CNC machine that runs solid for 30+ hours a week, 52 weeks a year.

This is PWI’s beam line robot, equipped with a plasma cutting torch that precisely cuts down structural steel profiles to their intended shapes. It is capable of cutting three sides of any structural steel profile including beams, channels, angle bars and tubing.

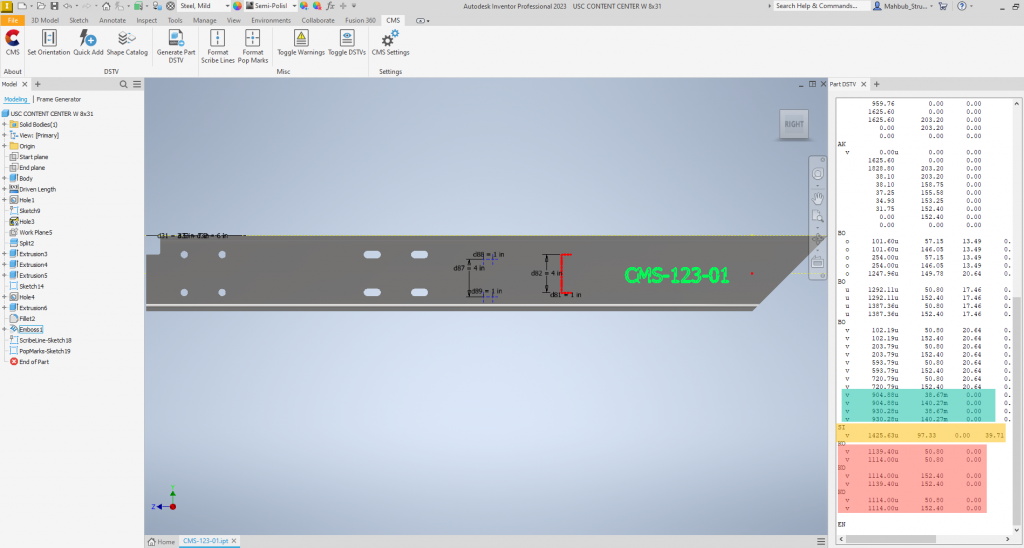

The structural steel profiles are designed using Autodesk Inventor. With 100s of files generated per day, PWI uses CMS for Inventor to process their designs and make them ready to be fabricated by their beam line robot.

CMS converts Autodesk Inventor files into the DSTV/NC1 extension—an industry standard file extension developed by the German Steel Association (Deutsche Stahlbau-Verband). It consolidates the file outputs of various CAD / CAM software (DXF, DWG, IPT,) into one standardized extension that is easily accessible by the majority of CNC machinery available in the current market.

PWI uses CMS for Inventor to convert these components:

- Stair stringers for industrial stairways

- Runway beams for overhead bridge cranes

- Main girder beams for overhead bridge cranes

- Unique projects processed using CMS for Inventor: 3,311

- Unique files generated using CMS for Inventor (including project quotes): 8300+

- Average 33+ files generated per workday

Automation is the name of the game

The design and fabrication of industrial stairways represents another profitable endeavor for PWI. In January 2021, the company launched a proprietary design automation platform by leveraging Inventor’s programming interface to generate industrial stairway models and drawings without manual input. CMS was also integrated into their platform, with each stairway component needing to be converted into the DSTV/NC1 format for their beam processing line.

By combining their in-house design platform with CMS for Inventor, PWI was capable of producing a complete set of shop drawings and CNC files, ready for production, taking their design automation to the next level. Pretty neat.

In short, we have loved our experience with CMS. The software is intuitive, easy to use, and works with 99% of our designs. To our knowledge, there is no other software available that can export files to DSTV/NC1 directly from Autodesk Inventor. But, the fact that it not only does it well but also very quickly is awesome, and we love it!” — Jeff Miller, Software Development Coordinator, PWI Works.

Jeff Miller - Software Development Coordinator, PWI Works

Learn more about PWI Works here

To find out more about CMS for Inventor, visit here.

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com