What is Custom Programming?

There is a software solution for every construction problem, however not all of those solutions are available right out of the box. Custom programming or in some cases custom software development, refers to the creation of bespoke software applications and functionality to meet a very specific set of requirements.

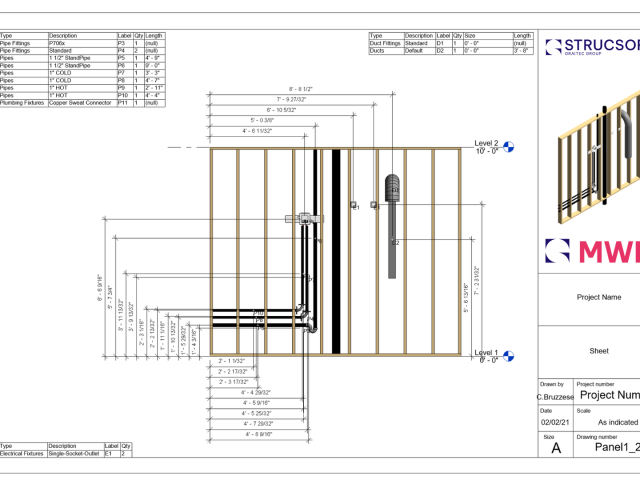

In the context of the built environment, this would apply to builders already using CAD or BIM software such as MWF, yet requiring specialized functionality to meet their goals: efficient automation, improved project timelines or a smoother link between the design, manufacture and assembly processes.

In this article we’ll look at how modular builders can advance their projects through custom programming solutions.

- Improved Workflow Automation

Whether it’s building wall kits for a hospital, a shopping center or a row of single family homes, prefabricated buildings allow for a great degree of automation during the manufacturing process, due to how standardized and repeatable they are by nature.

This gives the builder incentives to innovate upon existing processes, with the goal of improving cost savings, time schedules and addressing labor requirements.

For example, a modular builder may create bespoke wall framing kits in cold formed steel that come pre-insulated. This may not be the most common industry practice and would involve the use of custom machinery to manufacture the components, which existing software may not integrate with.

Also, the more automated the process, the greater weight is put on the accuracy of the design. Decisions that could be made later down the stream, need to be planned and addressed early on during the design phase. Rework is not a feasible option when manufacturing is already underway.

Using custom programming services a modular builder can create better integrations between their virtual models and machinery, be it a sheathing router, multifunction bridge or a custom CNC machine. Custom production sequences can be designed in order to better coordinate with project timelines.

There is a software solution for every construction problem. With this notion in mind teams are less constrained when trying to innovate or improve existing processes, as they can feel confident in leveraging software to resolve potential bottlenecks.

- Your processes are further streamlined

Custom software development helps builders achieve more efficient automation during the manufacturing and design stages.

Software such as MWF come with out of the box automation features, to quickly model framing in a fraction of the time it would take to do the same manually.

However modular builders can also use custom programming to develop bespoke functionality that is better suited to their particular design and manufacture process, thereby improving their delivery timelines.

This applies to builders that use patent protected processes or machinery. In this case the developer will create functionality that is for the exclusive use of the client.

Builders can also request features that are already in the roadmap, in which case they can be released at an earlier stage for that particular user.

- Post production logistics get simplified

For the modular builder, the story doesn’t end after the components are manufactured. Next they have to be transported from the shop floor to the jobsite for assembly.

Such as the case of our clients Dalcassians, who transported over 300,000 sq. ft. of cold formed wall kits for a 7 story residential project, that were modeled with MWF the framing was batched into various sections and delivered onto the jobsite as requested.

Each builder will choose to pack their fabricated components in various horizontal or upright configurations, also known as stacking and bundling.

These configurations can be made in advance by using software such as Onyx, however depending on your requirements, you may need a configuration that is not standardly available. These can be custom developed, allowing your team to transport components in a way that is better aligned with the nuances of the project.

While this article focuses on modular builders, StrucSoft’s custom programming services are used by a wide gamut of construction firms. Contact us to learn more about how we can innovate solutions for your upcoming projects.

MWF allows builders to create, coordinate, engineer and fabricate their woos and cold formed steel framing within the Autodesk Revit environment. With a toolset enabling workflow automation and seamless transitions from the screen to the shop floor, MWF is the complete software for the designer and manufacturer. Learn more about MWF here.

For more information on our products or design services, visit strucsoftsolutions.com, email us at info@strucSoftsolutions.com or call us at 514-538-6862

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.