5 steel framing landmarks

Continuing our series of the most Spectacular Steel Frame Buildings, this second part contains a blend of icons of global significance, both historical and contemporary.

Whether it be due to their sheer pioneering spirit, exceptional commitment to sustainable building design, or the zeal to be the biggest – we’ve included five more buildings that go above and beyond in showcasing the possibilities of steel (along with the help of concrete!) for the builders of today and tomorrow.

What is your favorite steel building? Let us know in the comments section below this article, or on our social media handles.

The Empire State Building

- Location: New York, USA

- Height: 443 m

The Empire State Building was envisioned to become the tallest skyscraper on earth, and edge out its main competitor vying for that title, the Chrysler Building. It achieved that goal and remained the tallest building in the world for 40 years, until the early 70s when the Twin Towers were completed.

The Empire State Building was envisioned to become the tallest skyscraper on earth, and edge out its main competitor vying for that title, the Chrysler Building. It achieved that goal and remained the tallest building in the world for 40 years, until the early 70s when the Twin Towers were completed.

It is one of the hallmarks of the Art Deco visual style (the other one being the more aesthetically pleasing Chrysler Building), which was in trend at the time in the 1920s and 30s. The skyscraper began making waves even before it was built, starting with the demolition of another cultural icon – the original Waldorf Astoria hotel, removed to make way for the construction of a greater giant in every sense of the word.

Steel Frame

The Empire State Building’s steel frame consists of 110 vertical columns, fastened to horizontal beams with rivets. The steel sections were prefabricated at a nearby steel mill and transported for assembly on-site. Heavier sections which couldn’t be lifted more than 30 stories at a time, required cranes and derricks to be transported to higher levels.

The construction workers, aptly called skyboys, worked in compact teams of four to quickly raise the steel framing in just 8 months. The entire building was constructed in a similar haste, in 1 year and 45 days, at a rate of 4.5 stories per week. Not only was it finished way ahead of schedule, but also under budget, costing USD 24.7 million instead of the originally budgeted USD 43 million.

The building was completed in the Spring of 1930, and opened to the public on May 1st, marking its 90th Anniversary in 2020.

Fun fact: Over a span of 6 months in 1993, the building earned over $3,000 dollars from visitors who would each pay 10 cents to enjoy the views provided by telescopes on the roof. Adjusted for inflation, in today’s U.S dollars this equates to a cool $65,000.

Shanghai Tower

- Location: Shanghai, China

- Height: 632 m

The Shanghai Tower’s smooth curvature stands in immediate contrast to its supertall and more angular neighbors – the Shanghai World Financial Center, somewhat resembling a giant bottle opener, and the Jin Mao Building with its unique pagoda-like exterior.

Serving as an office space and tourist destination, it is the tallest building in China at 632 m, and was the 2nd tallest in the world until recently, when the Merdeka 118 in Malaysia snatched that spot after topping out in December 2021 with a height of 679 m.

The Structure

The Shanghai Tower’s backbone is a 30 sq. m. concrete core, reinforced by structural steel framing in the form of outriggers and a belt truss system. The core is surrounded by 12 additional columns that are tied together, similar in concept to the bundling tube system used for the Willis Tower, featured in our previous article.

Shanghai, which is located in the Southern part of China, faces on average 7-8 typhoons a year. For a supertall building such as the Shanghai Tower, mitigating heavy lateral loads in the form of typhoon winds was one of the key contributors in shaping its exterior.

While both its neighbors are equally successful in warding off typhoon winds, the Shanghai Tower is taller than either of them and prone to facing stronger wind loads. For example, a building this tall can sway as much as 5 feet when facing typhoons, according to the builder Gensler. The building’s structure and shape helped reduce lateral loads to the tower by 24%, helping the tower save USD 58 million in material costs.

The tallest LEED Platinum Steel Frame Building

The topic of green buildings becomes unavoidable and more pertinent as we hurtle deeper into the 21st century. The U.S Green Building Council’s LEED certification system, initiated in 1993 continues to be the most popular ranking systems for green buildings, focusing on efficient resource usage, inhabitant health and reduced carbon footprints.

The Shanghai Tower is currently the tallest LEED Platinum certified building on the planet, the highest possible ranking in the program, however it shall very soon be surpassed by the Merdeka 118 which is slated to receive its platinum in the foreseeable future.

Some of its other features include the capability of harvesting rainwater atop the roof, wind turbines which conveniently convert heavy wind loads into energy, and multiple water treatment plants helping the building recycle 235,000 cubic meters of water a year.

One World Trade Center

- Location: New York, USA

- Height: 541 m

Designed in memory of and close to the site of the original Twin Towers, the One World Trade Center has a cubic base identical to its earlier counterpart, with the exterior form composed of 8 isosceles triangles curving to form an octagon in the middle of the structure. Its exterior design was inspired in part by the look of the unbuilt New York Stock Exchange Tower.

From base to the top of the roof excluding the spire, One World Trade Center is at the same height as the original Twin Towers at 418 m, while the tower’s architectural height is 541 meters, which when converted into feet becomes the symbolic 1776, the year of the signing of the Declaration of Independence.

The building’s central core is made of the highest strength concrete ever poured in New York at 14,000 PSI, with its perimeter reinforced by a steel moment frame. It uses 40,800 metric tons of structural steel, bolted and welded together for maximum structural strength.

Tallest Steel Frame Building in the Western Hemisphere

The tower is currently the tallest in the Western hemisphere, a superlative it has held since its completion in 2014, and the tallest building in New York.

The building also features several sustainability considerations. Some of those include what the builders Skidmore, Owings Merrell call “green concrete”, made from waste fly ash collected from coal plants. According to the Interesting Engineering blog 50% of the concrete was made from recycled industrial waste. About 50% of the wood used in this building was sourced from sustainably harvested forests, certified by the Forest Stewardship Council (FSC), and harvests practically all its rainwater for use in cooling, fire protection and landscape irrigation.

The Shard

- Location: London, UK

- Height: 310 m

For this entry we go across the pond to the UK, and take a look at the tallest building in the United Kingdom and Western Europe. Built as a ‘vertical city’, the Shard is a mixed use tower and the first of its kind in Europe, featuring office, hotels and some of the highest residential spaces in the UK.

The owner of the project had his own building, the Southwark Towers demolished to make way for what is today a landmark of modern London and a popular tourist attraction. It might not be the most well recognized one, that title belonging to what the locals adorably refer to as The Gherkin.

Its height, coupled with an all glass exterior made of 11,000 glass panels and sharp triangular spires lend well to the tower’s name. When viewed from the right angle, the spire seem to give the building a close resemblance to a bishop’s miter.

The building’s construction began in March 2009, and was completed in 2012 with its public inauguration in June by the Prime Minister of Qatar.

Top down construction

Steel framing comprises the first 40 levels of the hybrid building where the offices are located, while the basement and remaining 30 levels are made of reinforced concrete, and the topmost levels along with the crowning spire again made of steel.

The Shard was built top-down using a slip forming technique, where the substructure and superstructure (part of the building below ground level and above ground level respectively) were simultaneously built, with the basement floors getting constructed at the same time as the excavation continued. This swift method was key in helping the project save 3 months of building time, bringing its completion date from what was originally estimated to be after the Summer London Olympics, to just before. The resultant single concrete pour was also the largest ever in the UK.

Manitoba Hydro Place

- Location: Winnipeg, Manitoba

- Height: 115 m

At 22 stories and a height of 115 meters, the Manitoba Hydro Place in Downtown Winnipeg is the shortest and greenest entry in this list. Home to the province’s sole energy provider. It has been widely recognized in North America as an exceptional icon in sustainable building design.

From the very beginning, superior resource efficiency was mandated to the builders of this office building. The project’s target was to reduce energy consumption to 60% below Canada’s National Energy Code (MNECB), allowing Manitoba Hydro to save CAD 15 million in annual operating costs.

Construction on the building began in 2005 and was completed in 2011. The finished structure includes a solar chimney taller than the actual building, called the ‘Solar Tower’. A solar collector in one of the coldest cities in the world? Yes, in fact Winnipeg receives on average more sunlight than most Canadian cities including Toronto, Vancouver or our very own Montreal.

Green steel framing

In order to remain as cost and energy efficient as possible, building materials were sourced locally – such as Tyndall Stone from Manitoba quarries, and incorporated high levels of recycled materials. For example, the structural steel and reinforced steel framing members were made of 90% to nearly 100% recycled content.

It also has three, six story high winter gardens that provide the building 100% fresh outside air, throughout the year. Downtown Winnipeg has the windiest intersection in Canada, helping the Manitoba Hydro Place draw in all the air it needs to keep its inhabitants well ventilated. Temperature regulation through active radiant slabs, and utilizing Winnipeg’s abundant sunshine via the building’s glass walls, helps provide the necessary heating during winter. During the summer, windows are opened to allow air to naturally ventilate the building.

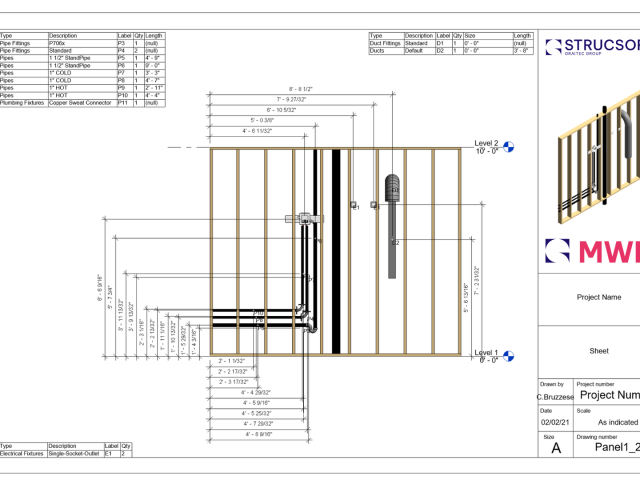

Steel framing is at the heart of what we do at Strucsoft Solutions. Our flagship product MWF is the industry leading Revit based wood and steel framing software providing professionals with world class solutions for over 20 years.

Learn more about MWF and its different modules here or see it in action and download your free trial here.

For more information on our products or design services, visit strucsoftsolutions.com/products or email us at info@strucsoftsolutions.com.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.