1. What is light gauge steel framing in construction?

Let’s break the term down. In the AEC industry, “framing” refers to the structural skeleton of a building, and the process of constructing it. At its most basic level, framing consists of a network of beams and columns.

This term is generally used in the context of timber or steel structures. It is less commonly used when referring to concrete, stone, or brick buildings–however it is worth noting that they may incorporate steel framing elements.

Light gauge steel, also known as cold formed steel is a popular building material that is used for creating both the structural and non-structural framing of a building. This thin and lightweight material is shaped into various profiles to create walls, floors, roofs and other elements for trusses. It is a popular material due to its high strength-to-weight ratio, durability and applicability to most types of construction projects.

2. What is the difference between tracks and studs?

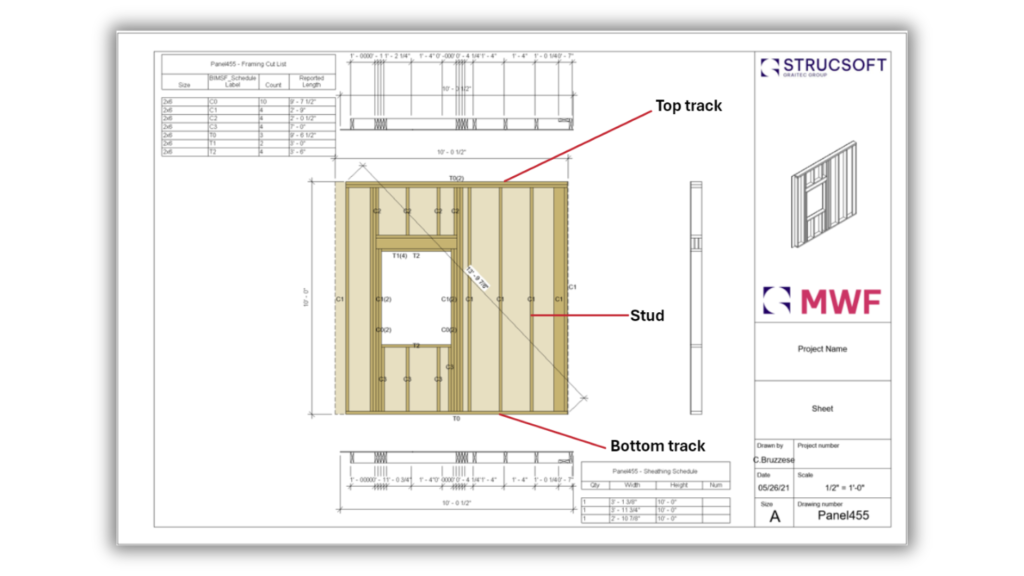

Tracks and studs are the fundamental components that make up a wall panel in light gauge steel framing. Tracks are horizontal structural components between which the vertical stud members are sandwiched.

This shop drawing depicts a wall panel with a window opening. The top track and bottom track span the entire length of the wall panel, and secure the vertical studs in place. Together, they provide the wall with enough structural stability to bear both vertical and horizontal loads.

3. What are the main advantages of light gauge steel framing?

LGSF construction offers various advantages to the builder including:

- High strength-to-weight ratio

- Lower transportation costs

- Can be machined for maximum precision

- Greater design flexibility compared to wood framing

- Sustainable material due to its unmatched recyclability

- Highly versatile material that is used in commercial, industrial and residential construction.

4. Are steel framed buildings built on-site?

Steel framed buildings are generally built offsite. This is a huge advantage for both the builder and the occupant for many reasons. If you are familiar with the following terms – offsite construction, modular construction or prefabrication – then this is exactly what is being referred to here.

Offsite fabrication allows the builder to design and manufacture components in a factory setting, thereby ensuring precision and high quality, while reducing errors and material waste. Once the construction site is prepped, the framing is shipped on site and installed in a short amount of time. The Modular Building Institute estimates 30-50% quicker construction times compared to traditional construction.

For the occupant, this results in significantly faster move-in times, and reduced inconvenience for the surrounding neighborhood, as the noise and obstructions caused due to on-site construction can be reduced to a large extent.

5. Can LGS Truss Design Software aid manufacturing processes?

Ensuring your software integrates into the manufacturing process is essential if your company handles all aspects of the construction process. This is a typical ask for modular or offsite construction companies that manage the design, fabrication and installation in-house.

If we’re talking about cold-formed steel (CFS) or timber trusses in specific, then you would require the software to be compatible with your roll-former or saw. Machine manufacturers may include Howick, Scottsdale, Beck, AMS Controls, Arkitech to name a few.

Software such as MWF Pro Metal and MWF Advanced Metal can be used to streamline the modeling and engineering of LGS trusses in Revit, generate shop drawings and export CNC data into manufacturing equipment.

Companies looking for an extensive solution to manage their manufacturing process can look to Onyx, a web-based manufacturing tool for MWF software, which can be used to manage CNC code, schedule work orders, and generate stacking and bundling templates for simplified material transport.

Simplify the design and fabrication of LGS framing with MWF Pro Metal

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com