Revit is one of the most widely used and comprehensive 3D modeling tools in the AEC industry. However, it is not a ‘one size fits all’ solution when it comes to manufacturing wood or metal framing.

More so for the constantly evolving offsite and modular construction sectors, where every sliver of speed and efficiency can make the difference between success or failure.

In this article we’ll look at how Revit framing plugins simplify the process of manufacturing wood or metal framing.

1. Design Faster with Revit Framing Plugins

While Revit’s base functionality is not specialized for modeling wood or steel framing, its feature set can be enhanced through plugins or add-ons.

This is where tools such as Revit framing software (or Revit framing plugins) come in to accelerate the modeling process. This results in designs that are precise and compatible with your manufacturing processes and machinery.

For example – consider the time required to manually design a metal or wood wall with openings for MEP elements, accurate stud spacing and intersections.

This workflow can be automated by using Revit framing software such as MWF Pro Metal, which uses a rule-based template driven approach to make this process significantly faster. These time savings are magnified on projects with thousands of wall and floor panels.

2. Enhance Inter-trade Collaboration

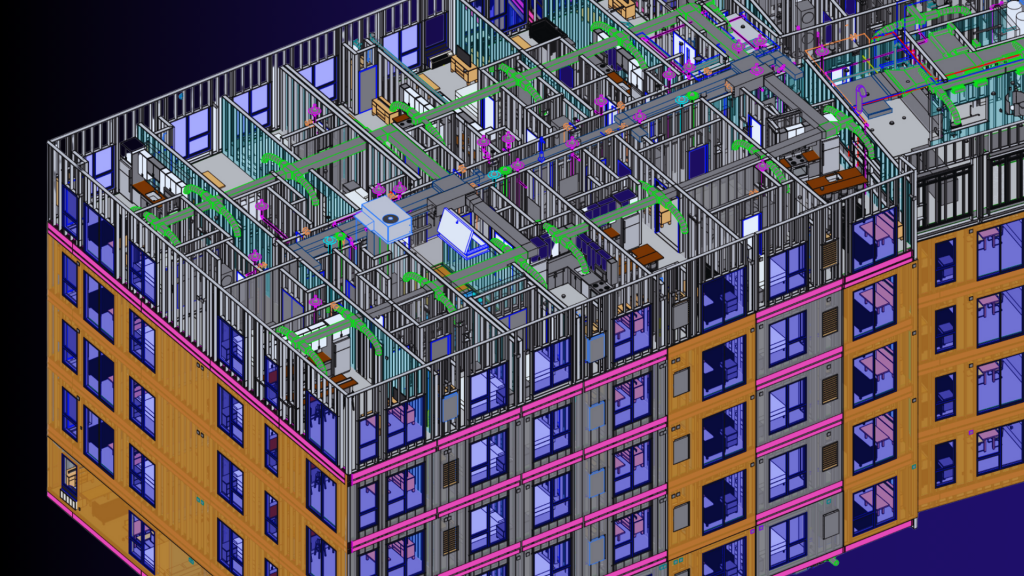

Ensuring maximum coordination between various teams and stakeholders when the framing is concerned, can be a challenging process. This challenge can get amplified on modular construction projects due to the complexities of this construction method.

Consider the creation of bathroom pods for a modular healthcare facility, where the mechanical, electrical and plumbing (MEP) systems need to be aligned perfectly before the manufacturing or construction process takes place.

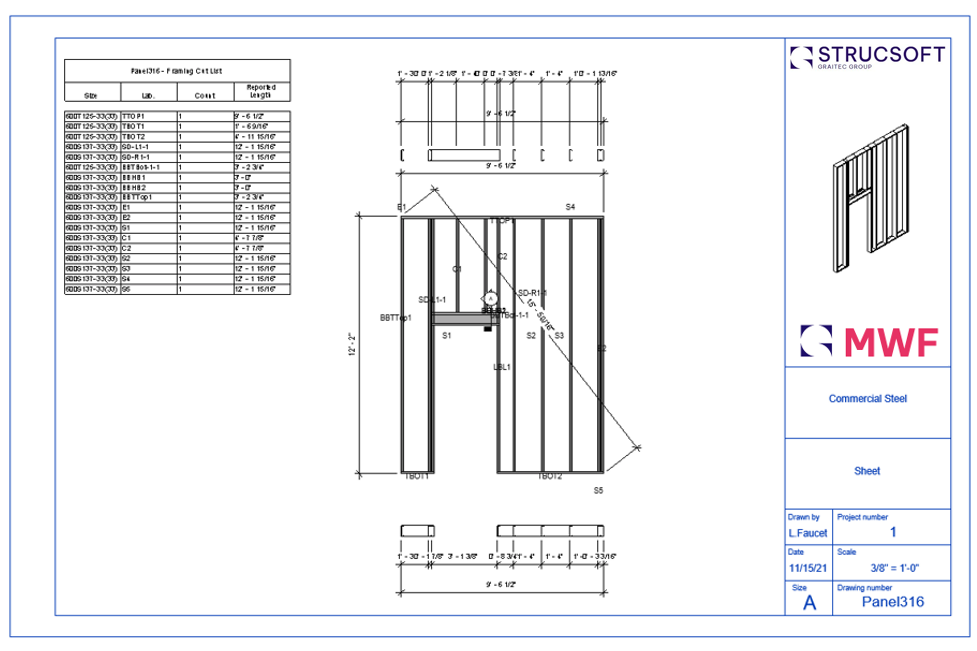

3. Generate Accurate Documentation

Generating documentation to aid both the manufacturing and construction process is a crucial step. These documents are essentially the blueprints for the entire construction project, providing precise instructions necessary for fabrication, assembly and installation.

This includes key documents such as material takeoffs, cutlists, bill of materials (BOMs) and reports. Instead of manually creating shop drawings, Revit framing software is capable of generating detailed and accurate shop drawings that are automatically updated once changes are made in a project.

4. Bridge Revit Models to Manufacturing

Equipment

Designing 3D models in Revit is one thing, ensuring that the modeled elements are optimized and compatible for fabrication, well that’s something else.

By designing your framing using software such as MWF, you are able to ensure that models are optimized and compatible for fabrication.

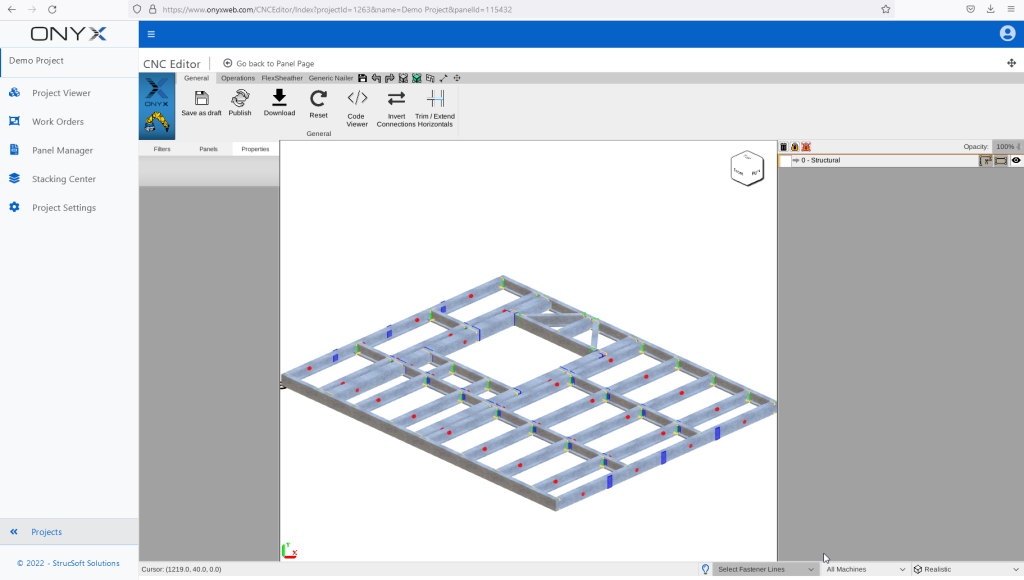

Once your Revit model is optimized and no further amendments are required, it is time to transfer your model to your machinery.

This is achieved through Onyx, a web-based extension for the MWF framing software, which enables users to edit CNC code, create work orders to generate optimized schedules, and much more.

The software is compatible with most machine manufacturers such as Howick, Scottsdale, Beck, Randek, Weinmann and more.

Users are also able to configure stacking and bundling templates for wall or floor panels, simplifying the process of transporting fabricated material to the job site for construction.

Elevate your manufacturing process to the next level with MWF framing software

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com