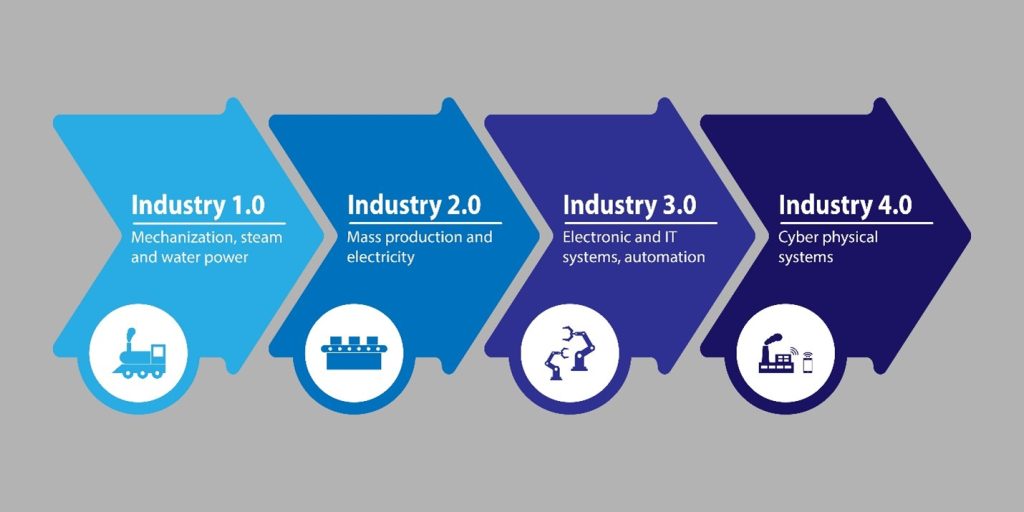

What is Industry 4.0

Industry 4.0 is the latest wave of innovation in manufacturing, where digital technologies enable smarter and more efficient production. It involves the integration of intelligent digital technologies into manufacturing and industrial processes. It encompasses a set of technologies that include industrial IoT networks, AI, big data, robotics, and automation.

Why is it important today?

The principles behind Industry 4.0 – interconnection of systems, data transparency, automation and sustainability – are transforming the entire supply chain, from smart factories and warehouses to smart logistics and delivery that incorporate AI capabilities.

Industry 4.0 History

First industrial revolution: Starting in the late 18th century in Britain, the first industrial revolution helped enable mass production by using water and steam power. Goods were built with machines rather than painstakingly produced by hand.

Second industrial revolution – the Technological Revolution: A century later, the second industrial revolution introduced assembly lines and the use of oil, gas and electric power. These new power sources, along with more advanced communications via telephone and telegraph, brought mass production and some degree of automation to manufacturing processes.

Third industrial revolution – the Digital Revolution: The third industrial revolution, which began in the middle of the 20th century, added computers and advanced telecommunications to manufacturing processes.

Fourth industrial revolution: We are now in the fourth industrial revolution, also referred to as Industry 4.0. Characterized by increasing automation and the employment of smart machines and smart factories, informed data helps to produce goods more efficiently and productively across the value chain.

How does Strucsoft Onyx fit in?

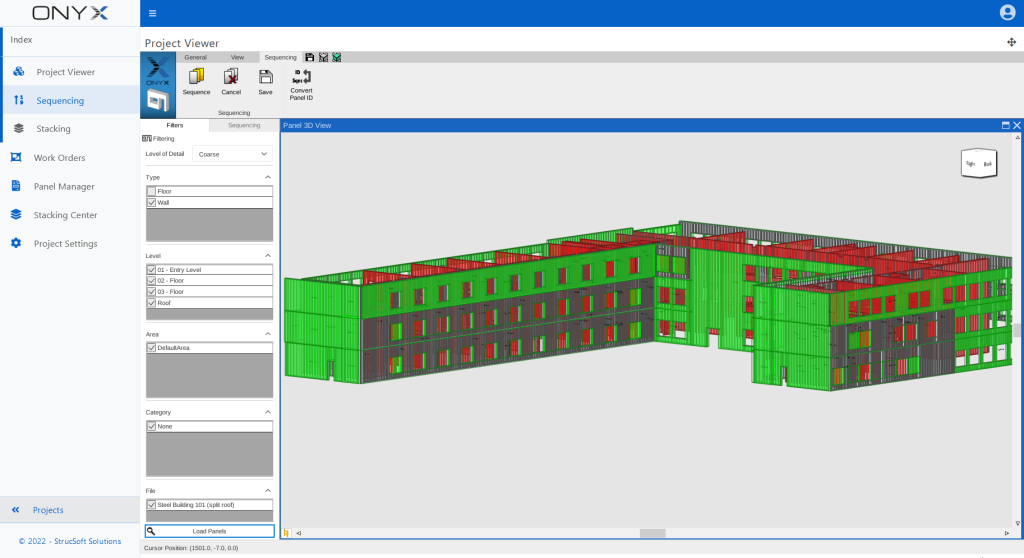

In the wake of the fourth industrial revolution, Strucsoft Onyx has emerged not merely as a product but as a pivotal force in the redefinition of global accessibility within the construction industry. Since its inception in 2019, Onyx has steadfastly bridged the distance between geographically dispersed production facilities and the intricate data they require, aligning perfectly with the ethos of Industry 4.0.

Onyx serves as the connective tissue among myriad facets of manufacturing, from initial design to the final construction phase. Following are the unparalleled achievements of Onyx in fostering a world where data and digital collaboration transcend physical boundaries.

Primary Aim: Crafting a cloud-based PDM solution that encapsulates the essence of global connectivity and data democratization, central to Industry 4.0.

Driving Philosophy: Ensuring every stakeholder, regardless of their location across the globe, can tap into the manufacturing pulse through Onyx, facilitating a seamless, interconnected digital ecosystem.

Onyx functionality

Cloud Infrastructure: Crafting a robust and adaptive cloud environment that embodies the omnipresence of data access, resonating with the globalized nature of contemporary construction practices.

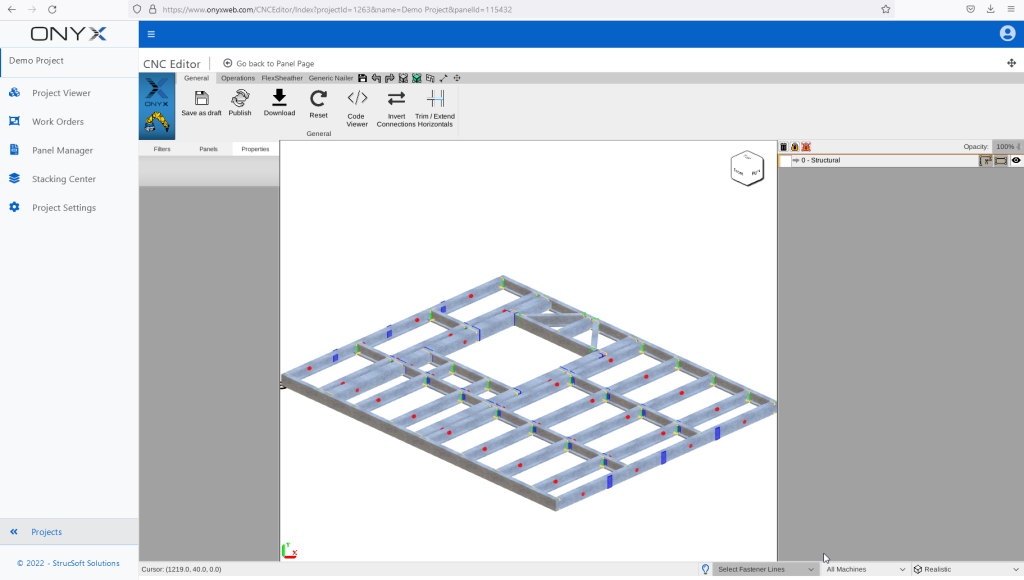

CNC File Accessibility: Pushing the envelope in manufacturing precision with CNC-prepared outputs from intricate Revit models, positioning Onyx as a pioneer in digital construction.

CNC Editor: The CNC Editor 2.0 boosts performance and lays the foundation for supporting multi-functional CNC machines like the Weinmann bridge, enhancing custom fabrication capabilities.

Multi-wall Output: Allowing for the generation of complex multi-wall assemblies, addressing advanced design demands, and providing unmatched flexibility in panel production.

Stacking and Bundling: Innovating the packaging and shipment of prefabricated components with 3D-enabled stacking and bundling features, optimizing material logistics from factory floor to construction site.

Enhanced Global Processes and Workflows:

- Data sovereignty: Onyx champions the concept of data sovereignty in the cloud, ensuring robust data management protocols that empower global teams.

- Agility in improvement: Adopting and exemplifying agile methodology, Onyx delivers regular enhancements, showcasing its agility and responsiveness to the rapidly evolving technological landscape.

- Worldwide support and adoption: Building a global support network that mirrors the international diversity of Onyx users, offering a multi-lingual platform that’s as versatile as the industry it serves.

Through the use of Onyx, flexibility is improved so manufacturers can better meet customer demands using mass customization—ultimately seeking to achieve efficiency with, in many cases, a lot size of one. By collecting more data from the factory floor and combining that with other enterprise operational data, a smart factory can achieve information transparency and better decisions.

For more information on our products or design services, visit strucsoftsolutions.com, or email us at info@strucSoftsolutions.com