Trusses are an integral part of wood or light gauge steel framing. As an architect, structural engineer or general contractor, designing roof or floor trusses is a crucial aspect of the construction process.

Keep reading to learn about what led to the development of trusses as we know them today, and how truss design software can accelerate and streamline your modeling and manufacturing processes.

What Is a Truss?

You can find them almost everywhere – bridges, stadiums, homes, even cranes and aircraft wings. They can be designed in virtually infinite configurations, but all trusses have something in common—they’re all made of triangles.

A truss is created when load bearing members are joined together to form a triangular configuration. The triangle is one of the strongest and most stable architectural shapes, particularly effective in resisting tension and compression loads.

Due to their naturally high strength to weight ratio, trusses are used in all sorts of load bearing applications. When it comes to light gauge steel or timber buildings, trusses are used to support roof and floor systems.

The History Of Trusses

From the roofs of Greek temples to the Pyramids of Giza, the triangle has been an integral part of human construction for thousands of years.

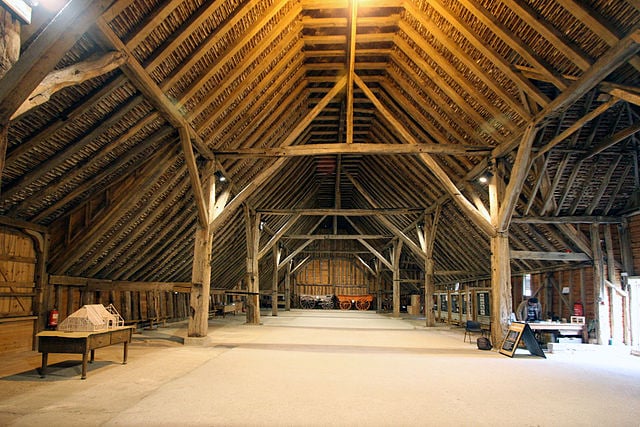

In medieval architecture we find that trusses were used to support the roofs of European cathedrals, and simple truss designs such as the king post can be found in structures from the 13th century, for example the Grange Barn in Essex, England. The Grange Barn is also cited as being one of the oldest surviving timber framed structures from that era.

Some of the earliest documented truss designs can be found in the notebooks of the celebrated artist Leonardo Da Vinci, where we can find drawings of several truss bridges. We also find truss designs in the classical Four Books of Architecture published in the 1570s.

It wasn’t until the railroad boom of the 18th century in the United States, that the truss as it is known today came into widespread existence.

The demand for covered bridges was so high that at its peak there were over 10,000 covered bridges in the United States. The construction of covered railroad bridges resulted in the creation and refinement of today’s modern timber truss systems.

Some of the most well known truss designs such as the Howe or Pratt were patented in the 18th century, with the goal of improving the design of existing covered bridges and covering wider spans.

While most covered bridges at the time were built using timber, newer designs started incorporating iron and steel, and also began introducing prefabrication methods for speedier construction.

Today trusses are commonly used in single and multifamily structures, both in wood and light gauge steel. Their triangular shape allows for efficient material usage, and the ample openings result in convenient placement of MEP services.

Take for example the tallest wooden building in the world – the Mjostarnet, featured in an earlier blog which uses glulam (glued laminated lumber) trusses to support its roof.

Revit Truss Design Software

A truss is formed when beams (also called top chords and bottom chords) are joined together with intersecting nodes (called webbing) to form triangular patterns. The connections between the webbing and chords, or ‘joints’, are subject to the greatest amount of loads.

Therefore, a major consideration in designing trusses is to ensure truss joints and connecting members can confidently withstand expected and unexpected loads without warping.

Using truss design software significantly reduces the complexity and time taken to ‘solve’ and ultimately design solid trusses.

Truss design software such as Everest can be used to quickly design and analyze light gauge steel trusses for users not working directly in the Revit® Environment. Builders who on the other hand utilize Revit for their framing workflows can use MWF Advanced Metal on the other hand is designed for those using Revit to frame their projects,

Truss Manufacturing

Truss software helps maintain a smooth workflow from the design phase, to fabrication and on-site assembly. Component data can easily be fed into roll formers or automated saw consoles to manufacture truss components with precision.

Construction documentation in the form of shop drawings, cut lists, bill of materials (BOM) allow on-site teams to install their framing efficiently.

Learn more about MWF Advanced Metal :

For more information on our products or design services, visit strucsoftsolutions.com/products, email us at info@strucSoftsolutions.com or call us at 514-538-6862

Interested in trying MWF Advanced Metal or Everest? Request your free trial:

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.

StrucSoft Solutions| Graitec Group is the market leader in comprehensive Autodesk® Revit®-based BIM framing, with both off-the-shelf and custom solutions targeting the AEC and fabrication sectors. Our star solution MWF simplifies complex Revit® framing with its powerful range of tools for modeling, inter-trade clash detection, custom construction documentation and optional output to CNC machines.