The trademark material for home building in North America and most parts of Europe is wood. The core element of any construction is wooden framing, and setting it up properly is the most significant part of the job. Modern home builders take advantage of the latest wood framing software to ensure that it is per the local building codes and ordinances.

The house framing aspect is a complex process, which depends on the size of the construction, levels, type of framing, etc.

Everything has to come together, from laminated lumber studs to foam-based adhesives and nails, so the entire structure is durable and lasts long. Otherwise, you may encounter problems like the doors not closing correctly or squeaky flooring.

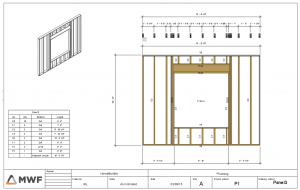

The template-based wood framing software from StrucSoft Solutions, MWF Pro Wood, is an efficient tool that lets you create custom framing. Apply the data automatically to your 3D project and achieve the highest level of precision.

What materials are used in home construction?

Various parts of the house may require different materials, such as steel, glass, wood and concrete. Each material has it’s own pros:

- Wood: Historically, building with wood has been the preferred material of choice. Wood construction application offers several natural advantages as it is one of the quickest, economical and flexible building materials. It is locally available and has a high rate of mobility. It has lower embodied energy, making it a natural thermal insulator. << Read more about the benefits of wood here >>

- Metal: Metal is a common building material for commercial buildings, skyscrapers, etc. It is ideal for larger buildings’ structural framework and can be used for roofing or external surface covering. Metal is fire-resistant, durable and can withstand adverse environmental conditions.

- Plastic: For plumbing and other uses in the home interior, plastic can work well with wood construction applications. Its properties like lightweight, low cost, etc. make it a popular material in the construction industry. However, it is highly flammable and not biodegradable.

- Cement: Cement is the primary ingredient in a concrete mix, but it is also used as a binder. Cement is suitable for all climatic conditions, as it accumulates heat better, and it is highly resilient. But it gathers dirt and moisture and can brittle with time.

- Glass: Contemporary and urban buildings use glass for beautification and create a feeling of openness. Glass is UV-resistant, energy-efficient and comes in several reflective surfaces to ensure your privacy. But the costs for purchase, installation and maintenance are high.

- Bricks: Bricks make for sturdy, fireproof foundations. However, they are quite heavy and vulnerable to moisture damage and mold.

Although brick and concrete are used for construction like roads, pools and other sturdy structures, people prefer wood for houses. Manufacturers and builders alike use wood framing software to improve the structural integrity of the overall build.

Types of wood framing

Homes built using pre-treated wood frames are considered “stick-built” homes. Before framing, concrete foundations are poured along the perimeter, which gives support to the home’s exterior walls. Builders sink beams into these slabs for the needed support for interior load-bearing walls. Wood construction applications use different types of framing:

- Balloon framing: Balloon framing characteristics are wall studs that run from the foundation to the entire height of the house. Although once popular, balloon framing is now replaced with platform framing. The primary reason for this shift is there is no way to prevent fire spreads between floors. Although, recently, builders are using metal framing to decrease fire risk.

- Platform framing: Here, a subfloor is built over the concrete foundation, and wood framing is laid over this subfloor. This method makes each floor independent and offers more construction stability. There is a lesser risk of a fire hazard. Unlike balloon framing, it does not require scaffolding to work on the upper floors.

Using software solutions in your next construction project

Whether you are a homeowner looking to renovate some area on your own or an established construction company, taking the help of the latest technology can make your job a whole lot easier.

Especially for residential elements, wood framing software can help you with the modelling, clash detection, engineering and manufacturing.

Who can use the software?

- General contractors

- Project managers

- Trade contractors

- Construction companies

- Custom home builders, etc.

Advantages of using wood framing software

Here’s why you should start using high-quality, specialized software for wood construction applications:

Analysis

You can analyze and design several framing elements like rafters, joists, beam-columns, load-bearing lumber walls and many more. Make virtually unlimited configurations to enhance accuracy and improve decision-making. You will be more productive when you have all the data.

Risk management

When you are using half-timber frames for construction, it is essential to plan and prepare ahead to minimize risks. For instance, you are constructing a circular turret tower on a house; many things could go wrong. From tracing the arc, radius and overhang run – everything needs precision. Modernized wood framing software can reduce this volatility.

Project management

With every large construction project, there may be some unexpected delays. Very rarely, there is a project that has no issues since it commences. By detecting the obstruction in the framing process, you can better manage time and resources.

Cost control

By eliminating or decreasing the issues, the project can finish within the budget. Utilize wood framing software to hit your target and reduce costs. There won’t be any redos after the initial inspection.

Eliminate errors at the construction site

Create intricate structural framing in a 3D model, with electrical and mechanical components. Integrate with any leading member sizing software or send the output to CNC machine interfaces. Contact StrucSoft Solutions today and get a free trial and leverage the benefits of wood framing software MW

For more information on our products or design services, visit strucsoftsolutions.com, email us at info@strucSoftsolutions.com or call us at 514-538-6862